1

Contents

Page No:

01

Why Hydroponics/Soil-less culture?

02

Hydroponics/Soil less culture - What is it?

02

History of hydroponics

03

Basic Requirements of Hydroponics

03

Classification of Hydroponics/Soil-less culture

04

Liquid or Solution Culture

04

Circulating Methods

04

Nutrient Film Technique (NFT)

05

Deep Flow Technique (DFT)-Pipe System

06

Non-Circulating Methods

07

Root Dipping Technique

10

Floating Technique

10

Capillary Action Technique

11

Solid Media Culture or Aggregate System

11

Hanging bag Technique (Open System)

12

Grow Bag Technique

13

Trench or Trough technique

15

Pot Technique

15

Aeroponic Technique

16

Nursery Techniques for hydroponics

17

Seed Germination

17

Planting material Production

17

Nutrient Supply

18

Nursery Period

18

Sponge Nursery Technique

2

...Contents

Page No:

19

Nutrient Solution for Soil-less culture

22

Electrical Conductivity (Ec)

22

Preparation of Nutrient Solution

23

Fertilizer Mixtures for Hydroponics

24

Fertigation

26

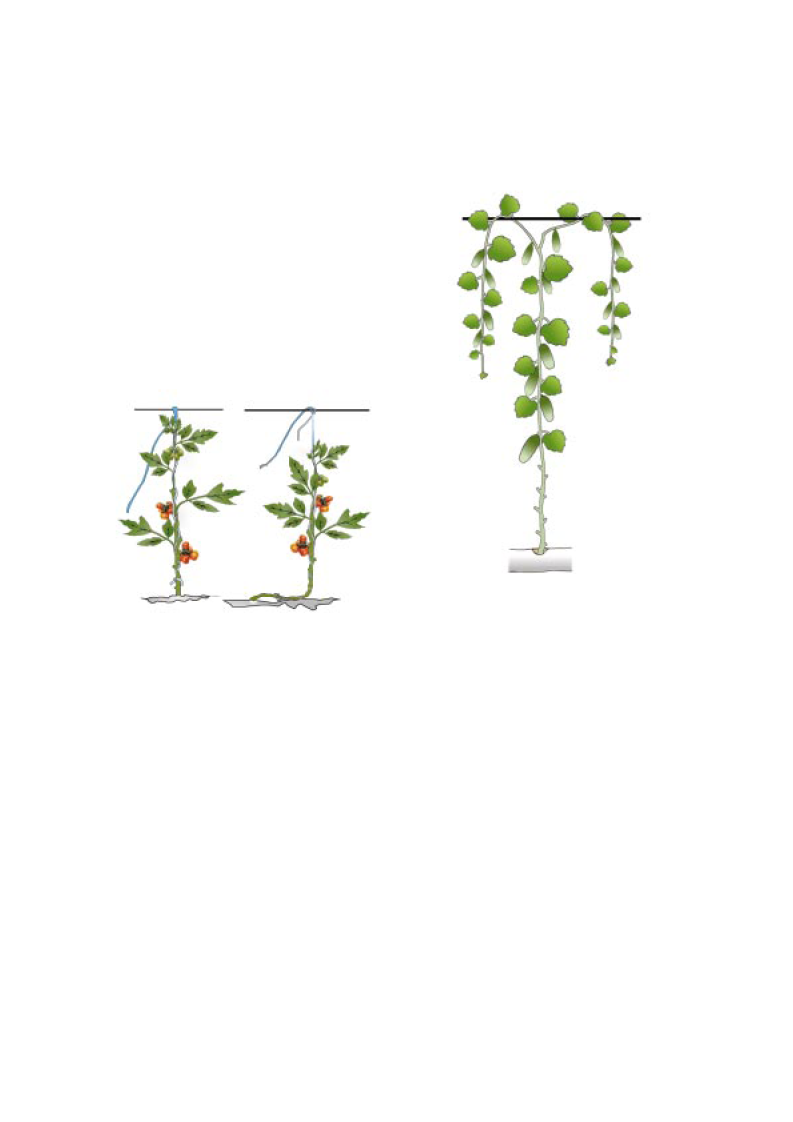

Training and Pruning

28

Management Requirements of Hydroponics/Soil-less culture

29

Soil-less culture and Controlled Environment agriculture

30

Some Problems and Solutions in Hydroponics

32

Insect Pest and Disease Damage in Hydroponics

32

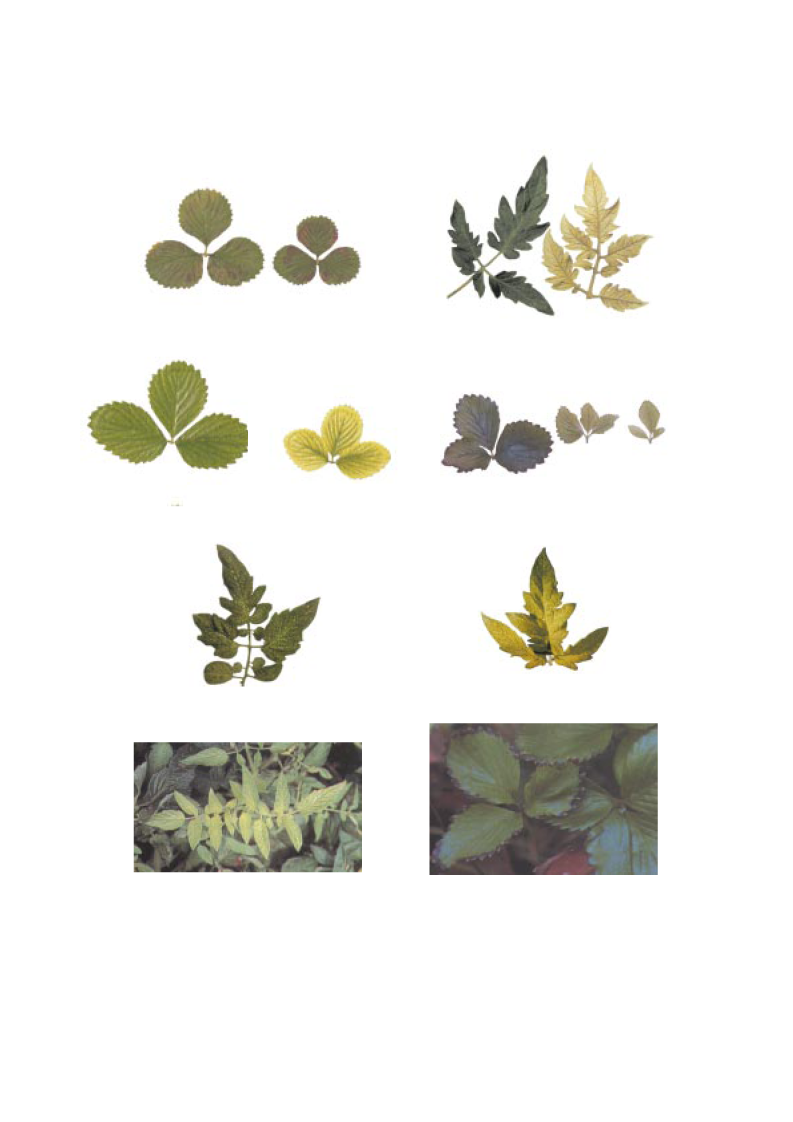

Nutritional Disorders

36

Advantages of Hydroponics/Soil-less culture

36

Limitations of Hydroponics/soil less culture

37

Crops to grow with Hydroponics/Soil-less Culture

37

Harvesting, Grading, Storage and Marketing

38

Equipments for Hydroponics

42

Acknowledgements

3

HYDROPONICS/

SOIL-LESS CULTURE

Air

A

e

n

g

h

r

Water

Nutrients

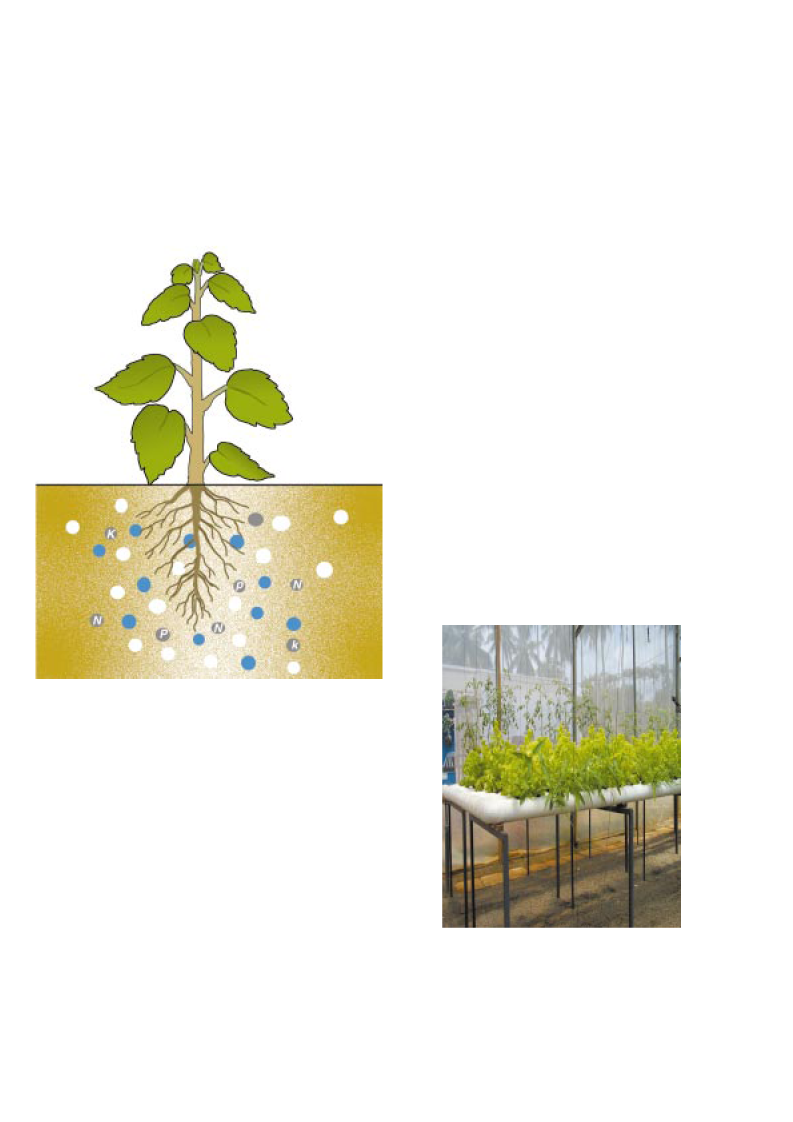

Figure 1: A plant grown in soil

Soil is usually the most available

growing medium and plants normally grow in

it. It provides anchorage, nutrients, air, water,

etc. for successful plant growth. Modification

of a soil an alternate growing medium tends

to be expensive. However, soils do pose

serious limitations for plant growth, at times.

Presence of disease causing organisms and

nematodes, unsuitable soil reaction,

unfavourable soil compaction, poor drainage,

degradation due to erosion, etc. are some of

them.

Further, continuous cultivation of crops

has resulted in poor soil fertility, which in turn

has reduced the opportunities for natural soil

fertility build up by microbes. This situation

has lead to poor yield and quality.

In addition, conventional crop growing

in soil (Open Field Agriculture) is difficult as it

involves large space, lot of labour and large

volume of water. And in some places like

metropolitan areas, soil is not available for crop

growing. Another serious problem experienced

since of late is the dif ficulty to hire labour for

conventional open field agriculture.

Why Hydroponics/

Soil-less Culture?

Hydroponics or soil-less culture is a

system of growing plants which helps reduce

some of the above mentioned problems

experienced in conventional crop cultivation.

Figure 2: Hydroponics lettuce plant

4

c

a

o

Hydroponics offers opportunities to

provide optimal conditions for plant growth and

therefore, higher yields can be obtained

compared to open field agriculture.

Hydroponics or soil less culture offers

a means of control over soil-borne diseases

and pests, which is especially desirable in the

tropics where the life cycles of these organisms

continues uninterrupted and so does the threat

of infestation. Thus the costly and time-

consuming tasks of soil sterilization, soil

amelioration, etc. can be avoided with

hydroponics system of cultivation. It offers a

clean working environment and thus hiring

labour is easy.

Hydroponics/

Soil-less Culture–

What is it?

Hydroponics or soil-less culture is a

technology for growing plants in nutrient

solutions that supply all nutrient elements

needed for optimum plant growth with or

without the use of an inert medium such as

gravel, vermiculite, rockwool, peat moss, saw

dust, coir dust, coconut fibre, etc. to provide

mechanical support.

Figure 3: Examples for hydroponics/ soil-less culture

History of Hydroponics

Hydroponics was practiced many

centuries ago in Amazon, Babylon, Egypt, china

and India where ancient men used dissolved

manure to grow cucumber, watermelons and

other vegetables in sandy riverbeds. The

“hanging harden of Babylon” and the Aztec’s

floating farms were actually prototypes of

hydroponic systems. Later, when plant

physiologists started to grow plants with specific

nutrients for experimental purposes, they gave

the name “nutriculture.”

Interest in practical application of

“nutriculture” developed in 1925 when the

green house industry expressed interest in its

use. Green house soils had to be replaced

frequently to overcome problems of soil

structure, fertility and pests. As a result,

researchers became interested in the potential

use of nutriculture to replace conventional soil

culture.

In 1929, Dr. William F. Gericke of the

University of California succeeded in growing

tomato vines of 7.5 m height in nutrient

solutions. He named this new production

system “hydroponics” a word derived from

Greek to reflect the importance of ‘Hydros’

(water) and ‘Ponos’ (working).

Thus,

hydroponics broke the laboratory bounds and

entered the world of practical horticulture. The

term hydroponics originally meant nutrient

solution culture. However, crop growing in inert

solid media using nutrient solution is also

included in hydroponics in broad sense.

During 1960s and 70s, commercial

hydroponics farms were developed in Abu

Dhabi, Arizona, Belgium, California, Denmark,

German, Holland, Iran, Italy, Japan, Russian

Federation and other countries. During 1980s,

many

automated

and

computerized

hydroponics farms were established around the

world. Home hydroponics kits became popular

during 1990s.

5

This requirement must be artificially maintained

in hydroponics. In any hydroponics system

the following basic requirements must be

maintained at optimum levels.

Buffer action of water or the inert

medium used.

The nutrient solution or the fertilizer

mixture used must contain all micro and

macro elements necessary for plant

growth and development.

Buffer action of the nutrient solution

must

be in the suitable range so that

plant root system or the inert medium is

not affected.

The temperature and aeration of the

inert medium or the nutrient solution is

suitable for plant root system.

Classification of

Hydroponics/

Soil-less Culture

The term hydroponics originally meant

nutrient solution culture with no supporting

medium. However, plant growing in solid media

for anchorage using nutrient solution is also

included in hydroponics. This technique is

called aggregate system. Hydroponics

systems are further categorized as open (i.e.,

once the nutrient solution is delivered to the

plant roots, it is not reused) or closed (i.e.,

surplus solution is recovered, replenished and

recycled). Current hydroponics systems of

cultivation can be classified according to the

techniques employed. A hydroponic technique

refers to the method of applying nutrient

solution to the plant roots.

Large numbers of hydroponic

techniques are available. However, consider

following factors in selecting a technique.

6

In Sri Lanka, the hydroponics system

of cultivation is in its infancy. Many use inert

solid medium such as coconut fibre or coir-dust

with fertigation and some use balanced nutrient

solution alone employing both circulating and

non-circulating methods in small and medium

scales.

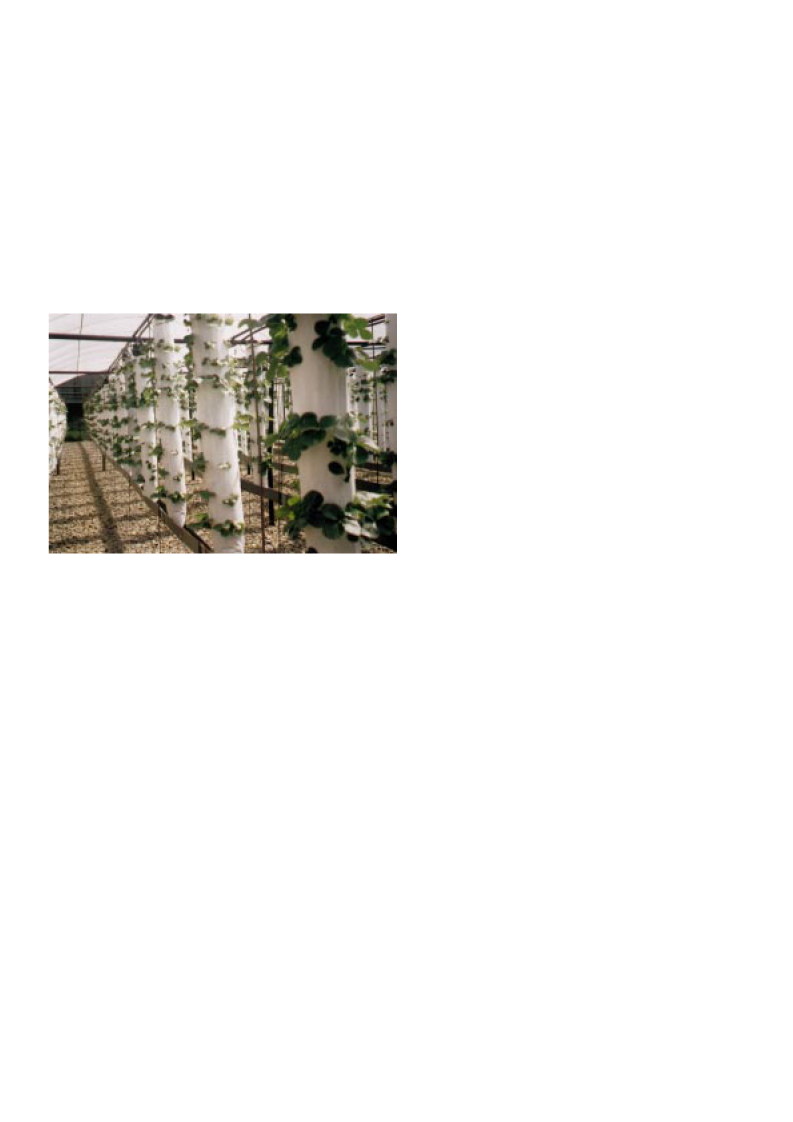

Figure 4: Hydroponics strawbery plants in a net house

Basic Requirements of

Hydroponics

Soils naturally maintain the temperature

and aeration needed for root growth. When the

soil is poor, plant growth and yield decline also

due to unsuitable aeration and temperature.

Plant cultivation is impossible under ill drained

condition due to these conditions. Soil adjusts

itself to provide suitable conditions for plant

growth. It is called the buffer action of the soils.

Plants also absorb nutrients released through

natural mineralization.

In a solution or inert medium,

maintenance of acidity or alkalinity (pH) and

electrical conductivity (Ec) in suitable ranges

for plant root system is called buffer action.

Space and other resources available

Expected productivity

Availability of suitable growing medium

Expected quality of the produce – colour,

appearance, free from pesticides, etc.

1. Solution culture or Liquid hydroponics

-Circulating methods (closed system)

Nutrient film technique (NFT)

Deep flow technique (DFT)

-Non-circulating method (open systems)

Root dipping technique

Floating technique

Capillary action technique

2. Solid media culture (Aggregate systems) –

These can be open systems or closed

systems.

-Hanging bag technique

-Grow bag technique

-Trench or trough technique

-Pot technique

3. Aeroponics

-Root mist technique

-Fog feed technique

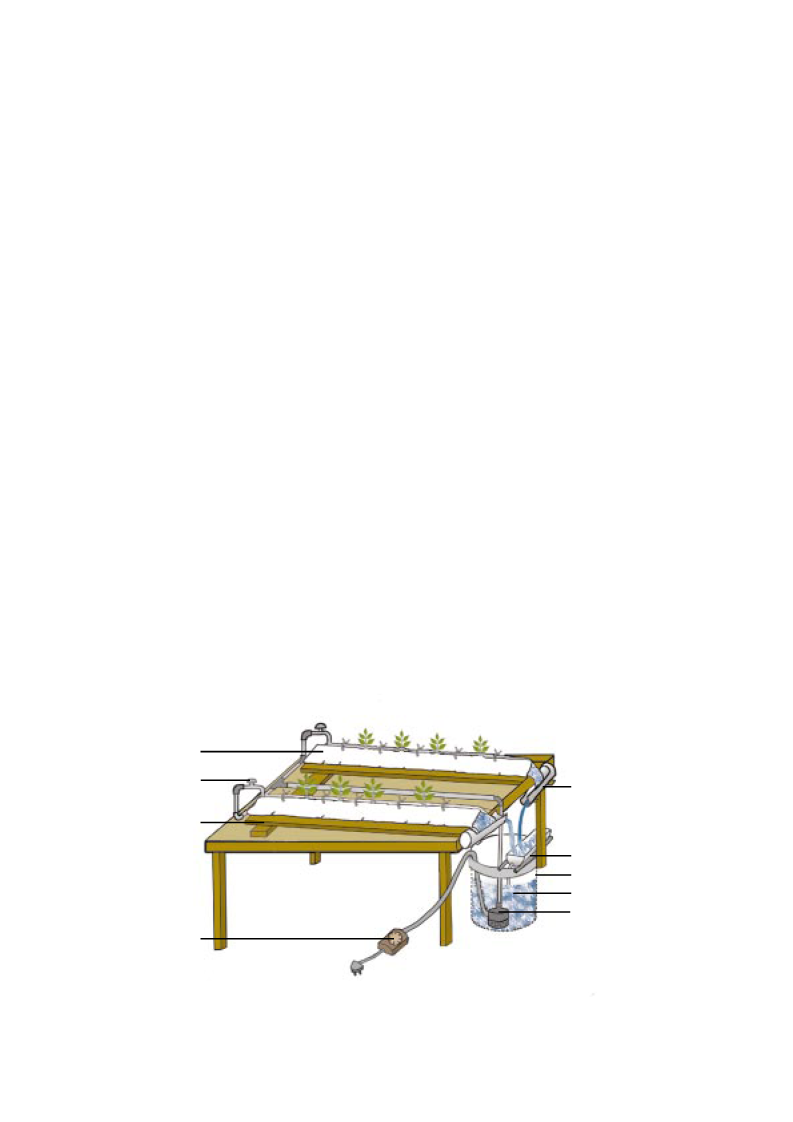

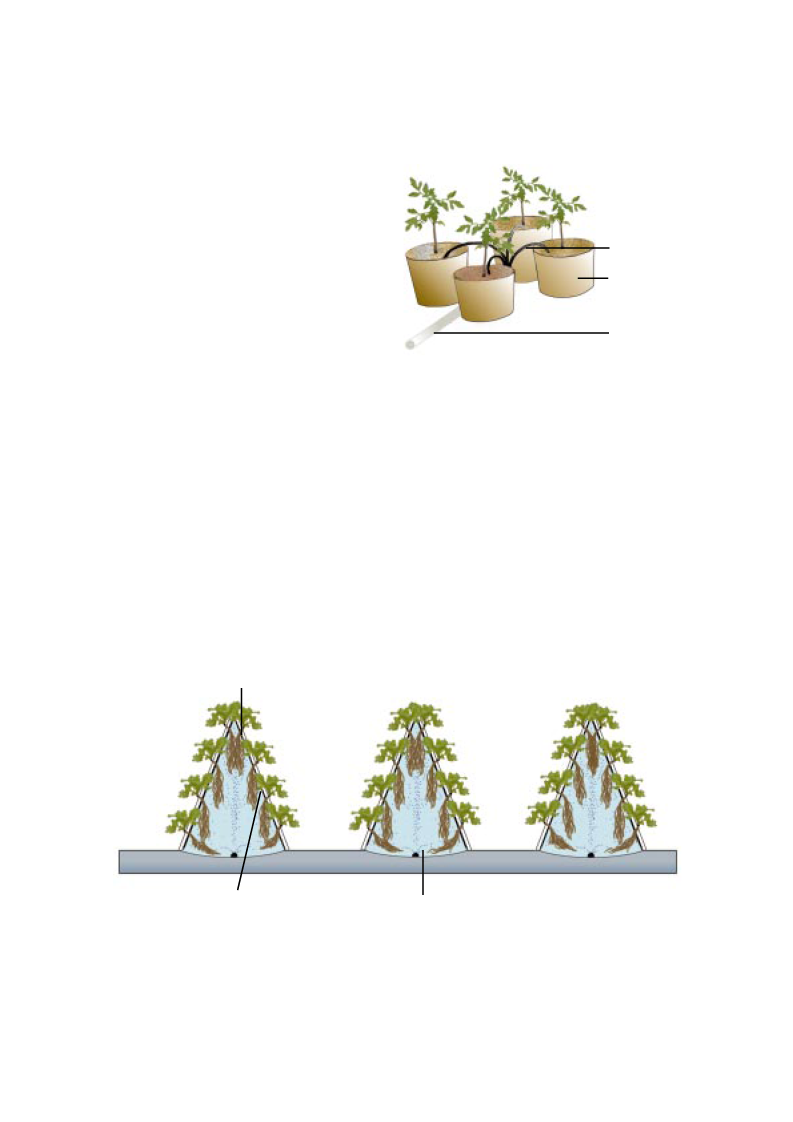

Channel made of

flexible sheet

Tap valve

Wooden plank

Timer

Liquid or Solution

Culture

CIRCULATING METHODS

The nutrient solution is pumped

through the plant root system and excess

solution is collected, replenished and reused

in these methods.

Nutrient Film Technique

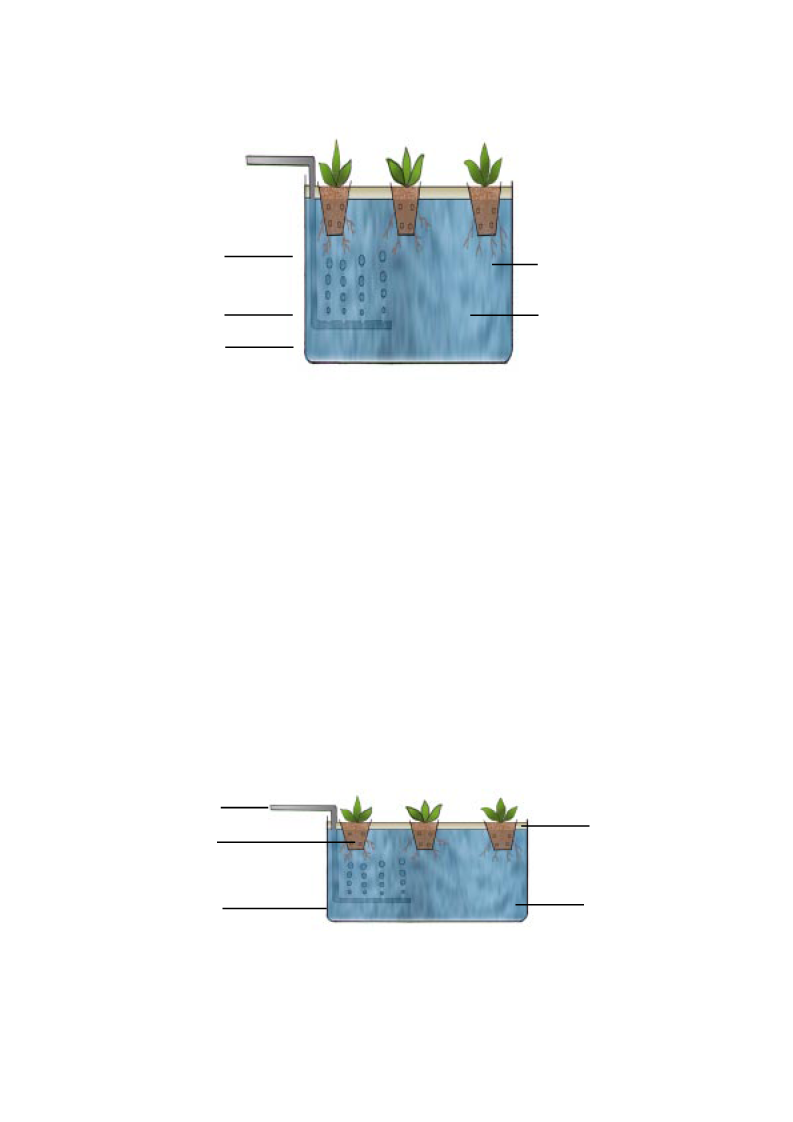

(NFT)

NFT is a true hydroponics system

where the plant roots are directly exposed to

nutrient solution. A thin film (0.5 mm) of nutrient

solution flows through channels. The main

features of a NFT system are shown in figure

5.

The channel is made of flexible sheet.

The seedlings with little growing medium are

placed at the centre of the sheet and both

edges are drawn to the base of the seedlings

and clipped together (Figure 6) to prevent

evaporation and to exclude light. The cross

section of the channel is shown in figure 7.

The growing medium absorbs nutrient solution

for young plants and when the plants grow the

roots form a mat in the channels.

PVC pipe

Sieve

Solution container

Nutrient solution

Submersible pump

Figure 5: Main features of a NFT system

7

Clip

Figure 7: Cross Section of a NFT channel

In practice, it is very difficult to maintain

a very thin film of nutrient solution and therefore,

this technique has undergone several

modifications.

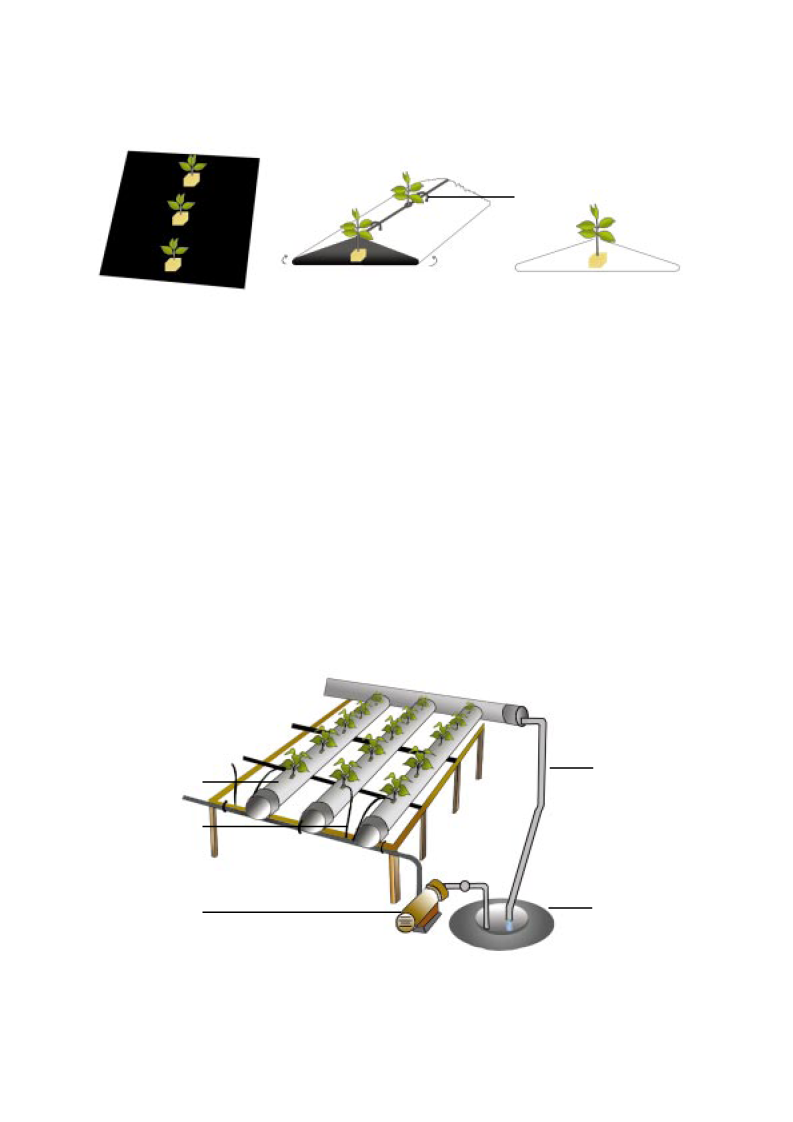

Deep Flow Technique (DFT)

– Pipe System

As the name implies, 2-3 cm deep

nutrient solution flows through 10 cm diameter

PVC pipes to which plastic net pots with plants

are fitted. The plastic pots contain planting

materials and their bottoms touch the nutrient

solution that flows in the pipes. The PVC pipes

may be arranged in one plane or in zig zag

shape depending on the types of crops grown.

The figure 8 and 10 below shows the main

features of a DFT – pipe system.

Drainage pipe to

send recycled

solution to the tank

Underground nutrient

solution stock tank

→

Figure 6: Basic structures of a NFT channel

The maximum length of the channel is

5-10 m and is placed at a slope drop of 1 in 50

to 1 in 75. The nutrient solution is pumped to

the higher end of each channel and flows by

gravity to the lower end wetting the root mat.

At lower end of the channels nutrient

solution gets collected and flows to the nutrient

solution tank. The solution is monitored for

salt concentration before recycling. Some

growers replace the nutrient solution every

week with fresh solution.

Adjust the flow rate of the nutrient

solution to 2-3 litres per minute depending on

the length of the channel. Provide enough

support for tall growing plants in this technique.

100mm PVC pipe

painted white

Delivery tube

Pump

Figure 8: An illustration of a single plane pipe system DFT

8

Figure 11: A zig zag pipe system DFT

Dranage pipe to

send recycled

solution to the tank

Underground

nutrient solution

stock tank

Figure 9: A Single plane pipe system DFT

The zig zag system utilizes the space

efficiently but suitable for low growing crops.

The single plane system is suitable for both tall

and short crops.

Delivery tube

PVC pipe

painted

white

Pump

Figure 10: An illustration of a zig zag pipe system DFT

9

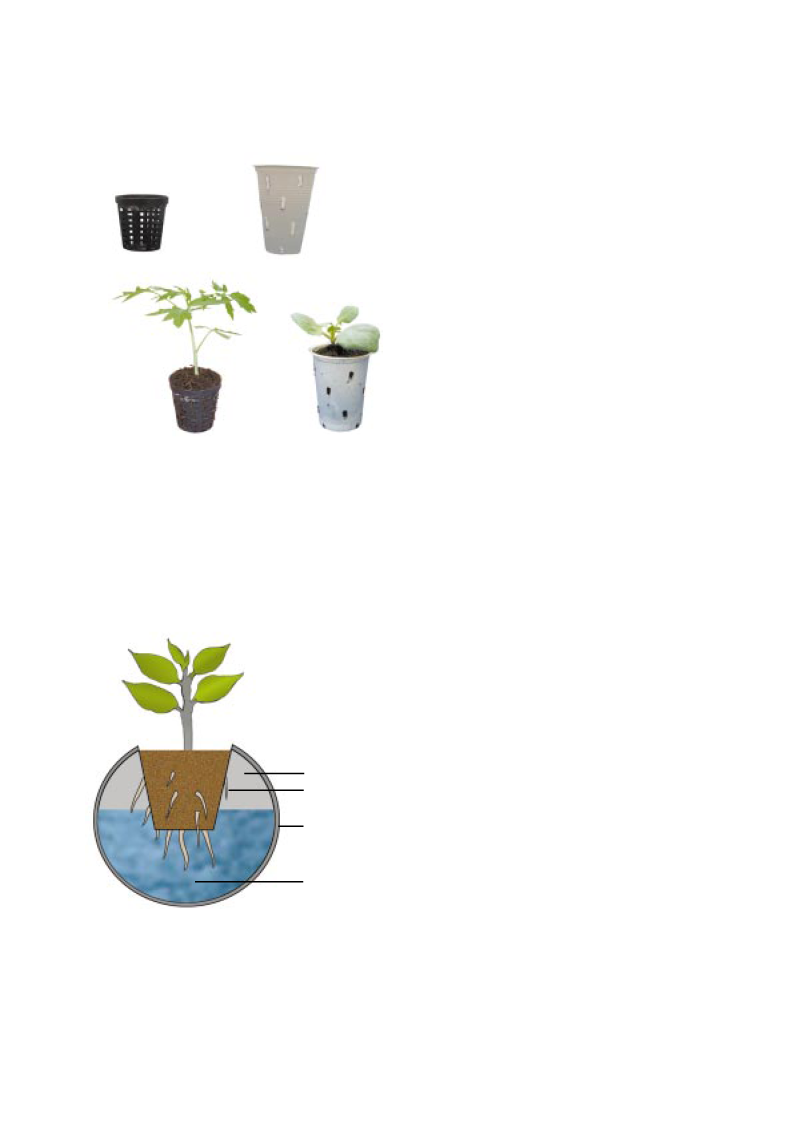

Net pot

plastic pot

Plastic pot with

established plant

Net pot with established

plant

Figure12

lining in the net pots to prevent the planting

material falling into the nutrient solution. Small

plastic cups with holes on the sides and bottom

may be used instead of net pots.

When the recycled solution falls into the

solution in the stock tank, the nutrient solution

gets aerated. The PVC pipes must have a

slope of drop of 1 in 30-40 to facilitate the flow

of nutrient solution. Painting the PVC pipes

white will help reduce the heating up of nutrient

solution. This system can be established in

the open space or in protected structures as

part of CEA.

NON-CIRCULATING

METHODS

The nutrient solution is not circulated

but used only once. When its nutrient

concentration decreases or pH or Ec changes,

it is replaced.

Root Dipping Technique

In this technique, plants are grown in

small pots filled with little growing medium. The

pots are placed in such a way that lower 2 - 3

cm of the pots is submerged in the nutrient

solution (figure 14). Some roots are dipped in

the solution while others hang in the air above

the solution for nutrient and air absorption,

respectively.

This technique is easy and can be

developed using easily available materials.

This ‘low tech’ growing method is inexpensive

to construct and needs little maintenance.

Importantly, this technique does not require

expensive items such as electricity, water

pump, channels, etc. For root crops (beet,

raddish, etc.) however, an inert medium has to

be used.

10

Plants are established in plastic net pots

and fixed to the holes made in the PVC pipes.

Old coir dust or carbonised rice husk or mixture

of both may be used as planting material to fill

the net pots. Place a small piece of net as a

Air space

Air absorbing

roots

PVC pipe

Nutrient

solution

Figure 13: Cross section of a PVC pipe system DFT

Planting pot

Planting medium

Air absorbing roots

Nutrient absorbing roots

Figure 14: Diagrammatic view of a non-circulating hydroponics non-root tuber plant

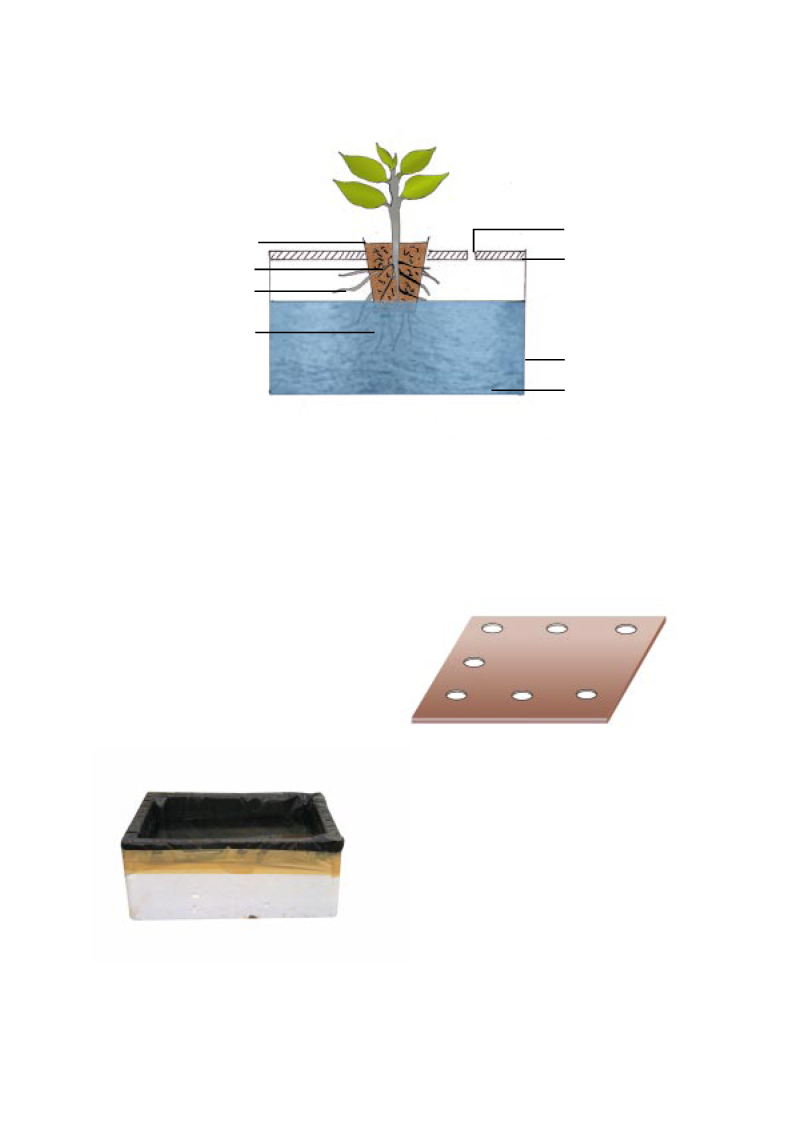

Hole for air passage

and refilling

A board to cover

container and to fix

planting pots

Container

Nutrient solution

A board is required to place on the

container to prevent light penetration. The

planting pots are also fixed to this board (figure

16). The number of holes in the board to fix

the pots depends on the crops to be grown.

An additional hole is necessary for air

circulation and refilling.

Figure 16: Boards with holes to cover the box and

to which pots are fixed

Seedlings are transplanted in plastic

pots filled with sterilized old coir-dust or

carbonised rice husk or the mixture of the two.

Plastic net pots or plastic cups can be used.

Make some holes at the bottom and on

sides of the plastic cups for roots to emerge

and for the nutrient solution to seep into the

11

1.

Root dipping technique for

non-root tuber crops

First, select a container for nutrient

solution. The container can be almost any

kind and shape except metal containers.

Styrofoam or wooden boxes, plastic buckets

or even cement troughs can be used.

Styrofoam boxes are good as they can maintain

the temperature of the nutrient solution. Place

a black plastic sheet of at least 0.15 mm

thickness as lining inside the boxes to avoid

leakage and to reduce the light (figure 15).

The depth of the box must be about 25 – 30

cm to provide enough solution as well as

enough space above the solution for oxygen

absorbing roots.

Figure 15: Container with black polythene lining

Maintain adequate air space above the

nutrient solution in the container. Success of

the non-circulating hydroponics system

depends on the rapid growth and quantity of

roots that are exposed to the air. These roots

absorb oxygen for the plants. Ideally, top two

Figure 19: Non-circulating hydroponic plants

growing in a Styrofoam box

thirds of the young root system must be in the

air and the rest must be floating/dipping in the

nutrient solution.

During crop growth, when the solution

level in the container goes down, the ion

concentration may increase. Such increase is

detrimental to plant growth. If this condition is

observed, siphon out the remaining solution

and refill with fresh solution.

2.

Root dipping technique for

root tuber crops

A 20 – 30 cm deep container can be

used. It is lined with black polythene sheet

and filled 1/3rd with nutrient solution. Leaving

a space of about 7.5 cm above the solution

level, fix a wire mesh in the box and fill with an

inert medium (Figure 20). The seedlings/seeds

are planted in the medium.

12

potting material (figure 17). Place a small

piece of net inside the pots or cups to prevent

potting materials falling into the solution. Seeds

could also be planted directly in the pots to

raise the crop.

Fill 2/3rd of the container with nutrient

solution. The pots with the plants are fitted on

to the board as shown in figure 18 and will be

placed on top of the box. Only the bottom 2

cm of the pots will be submerged in nutrient

solution.

Figure 17: planting pots

The above steps complete the formation

of non-circulating hydroponics system. These

boxes can be placed in net houses or in open

space or under rain shelters or in-door. Tall

growing plants will require some support to

prevent from falling.

Figure 18: Potted plants fixed to the board to

cover the container

Wire mesh

Perforated tube fill

with gowing medium

which will be removed

letter

Figure 20: Diagrammatic view of the root dipping technique for root tuber crops

At the early stage, nutrient solution will

reach the planting medium through the

perforated PVC pipe filled with the growing

medium by capillary action. Later, plant roots

will grow into the nutrient solution through wire

mesh. At this stage, the perforated tube will

be removed. The resulting hole will facilitate

aeration and refilling.

Floating Technique

This is similar to box method but

shallow containers (10 cm deep) can be used.

Plants established in small pots are fixed to a

Artificial

aeratiobn

Planting pots fixed

to styrofoam board

Container

Styrofoam sheet or any other light plate and

allowed to float on the nutrient solution filled in

the container (Figure 21) and solution is

artificially aerated.

Capillary Action Technique

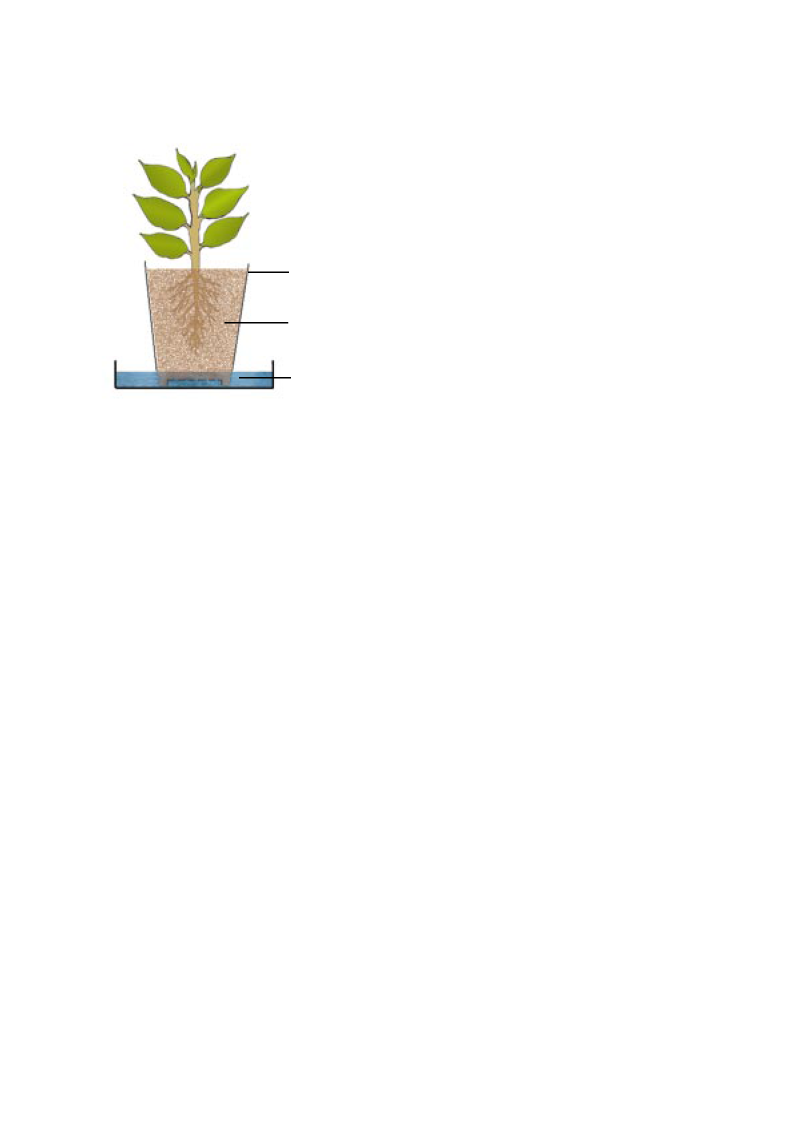

Planting pots of different sizes and

shapes with holes at the bottom are used. Fill

these pots with an inert medium and plant

seedlings/seeds in that inert medium. These

pots are placed in shallow containers filled with

the nutrient solution. Nutrient solution reaches

inert medium by capillary action (Figure 22).

Aeration is very important in this

technique. Therefore, old coir dust mixed with

sand or gravel can be used. This technique is

suitable for ornamental, flower and indoor

Styrofoam board

floating innutrient

solution

Nutrient

solution

Inert growing

medium

Air space

Nutrian Solution

Figure 21: Diagrammatic view of floating technique

13

Container with

holes at bottom

Highly porous

growing medium

Nutrient solution

Figure 22: Capillary action technique

plants.

Solid Media Culture or

Aggregate System

The following techniques involving

inert solid media can be practiced using locally

available materials. The media material

selected must be flexible, friable, with water

and air holding capacity and can be drained

easily. In addition, it must be free of toxic

substances, pests, disease causing

microorganisms, nematodes, etc. The medium

used must be thoroughly sterilized before use.

•

Inorganic natural media (gravel

culture)

•

Organic natural media (smoked rice

husk, saw dust, coconut fibre, coir dust

peat moss)

•

Inorganic artificial media (rockwool,

perlite, vermiculite)

•

Organic artificial media (polyurethane,

polyphenol, polyether, polyvinyl)

Tanins and acids present in the newly

extracted coir-dust affect plants. Therefore,

use at least 06 months old coir-dust. Dry, clean

compressed coir-dust blocks are available for

sale in the market.

Different techniques described below,

according to the method of holding the planting

medium, can be practiced.

Hanging Bag Technique

(Open system)

About 1 m long cylinder shaped, white

(interior black) UV treated, thick polythene

bags, filled with sterilized coconut fibre are

used. These bags are sealed at the bottom

end and tied to small PVC pipe at the top.

These bags are suspended vertically

from an overhead support above a nutrient

solution-collecting channel. Therefore, this

technique is also knows as ‘verti-grow’

technique. Seedlings or other planting materials

established in net pots are squeezed into holes

on the sides of the hanging bags. The nutrient

solution is pumped to top of each hanging bag

through a micro sprinkler attached inside the

hanging bags at the top. This micro sprinkler

evenly distributes the nutrient solution inside

the hanging bag. Nutrient solution drips down

wetting the coconut fibre and plant roots.

Excess solution gets collected in the channel

below through holes made at the bottom of the

hanging bags and flows back to the nutrient

solution stock tank (Figure 23).

This system can be established in the

open space or in protected structures. In

protected structures, the hanging bags in the

rows and amongst the rows must be spaced

in such a way that adequate sunlight falls on

the bags in the inner rows.

14

Hanging bags

filled with coir

fiber

Recycled

nutrient solution

Underground nutrient solution stock tank

Figure 23: Diagrammatic view of hanging bag technique

Nutrient

solution

delivery pipe

Pump

Figure 24: Strawbery plants growing in

hanging bags

The bags are not heavy as they are filled

with coconut fibre and can be used for about

02 years. The number of plants per bag varies

depending on the plants. About 20 lettuce

plants can be established per bag. This system

is suitable for leafy vegetables, strawberry, and

small flower plants. Black colour tubes will have

to be used for nutrient solution delivery to

prevent mould growth inside.

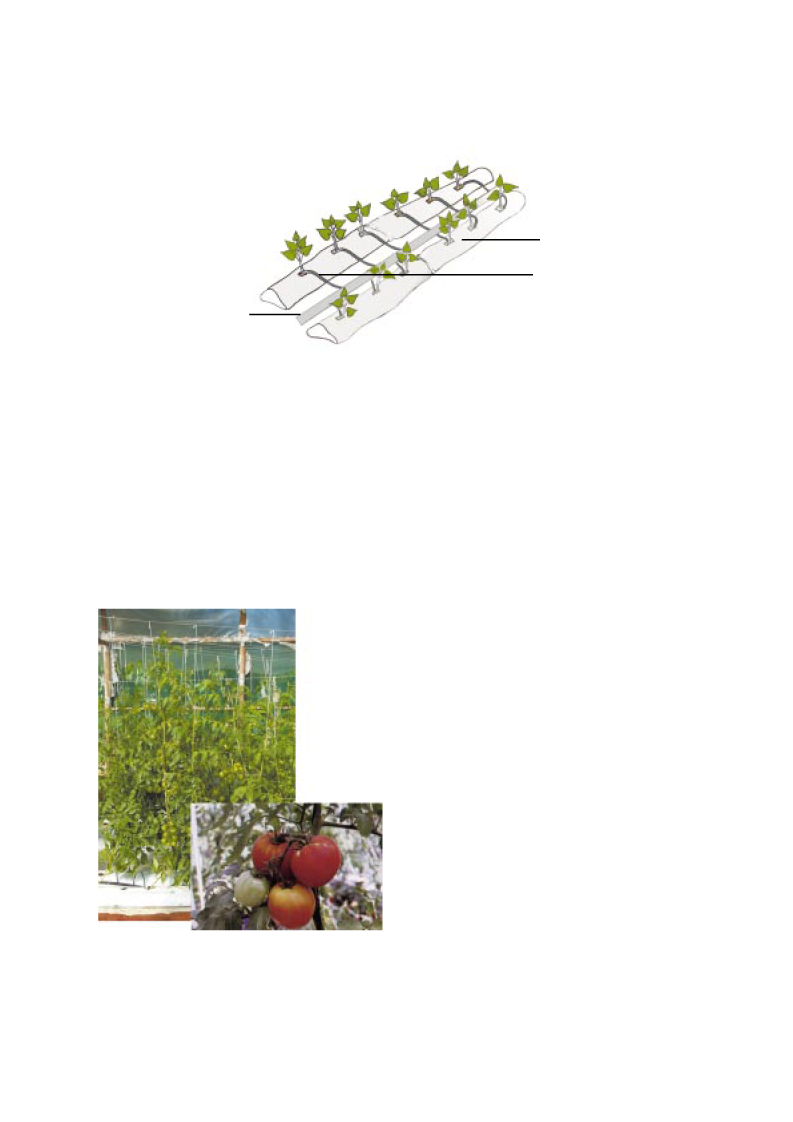

Grow Bag Technique

In this technique 1 – 1.5 m long white

(inside black), UV resistant, polythene bags

filled with old, sterilized coir-dust are used.

These bags are about 6 cm in height and 18

cm wide. These bags are placed end to end

horizontally in rows on the floor with walking

space in between (Figure 25). The bags may

be placed in paired rows depending on the

crop to grow.

Make small holes on the upper surface

of the bags and squeeze seedlings or other

planting materials established in net pots into

15

the coir-dust. 2-3 plants can be established

per bag. Make 02 small slits low on each

side of the bags for drainage or leaching.

Fertigation with black capillary tube

leading from main supply line to each plant is

practiced. The nutrient solution and water may

also be added manually to these bags.

Depending on the stage of crop growth and

the prevailing weather conditions, vary the

Figure 26: Tomato plants growing in grow bags

amount of water applied. Make sure that the

growing media is not completely saturated with

water or nutrient solution, as it prevents the

oxygen supply to plant roots.

Cover the entire floor with white UV

resistant polythene before placing the bags.

This white polythene reflects the sunlight to

the plants. It also reduces the relative humidity

in between plants and incidence of fungal

diseases. When tall growing plants are

established supporting structures will be

necessary.

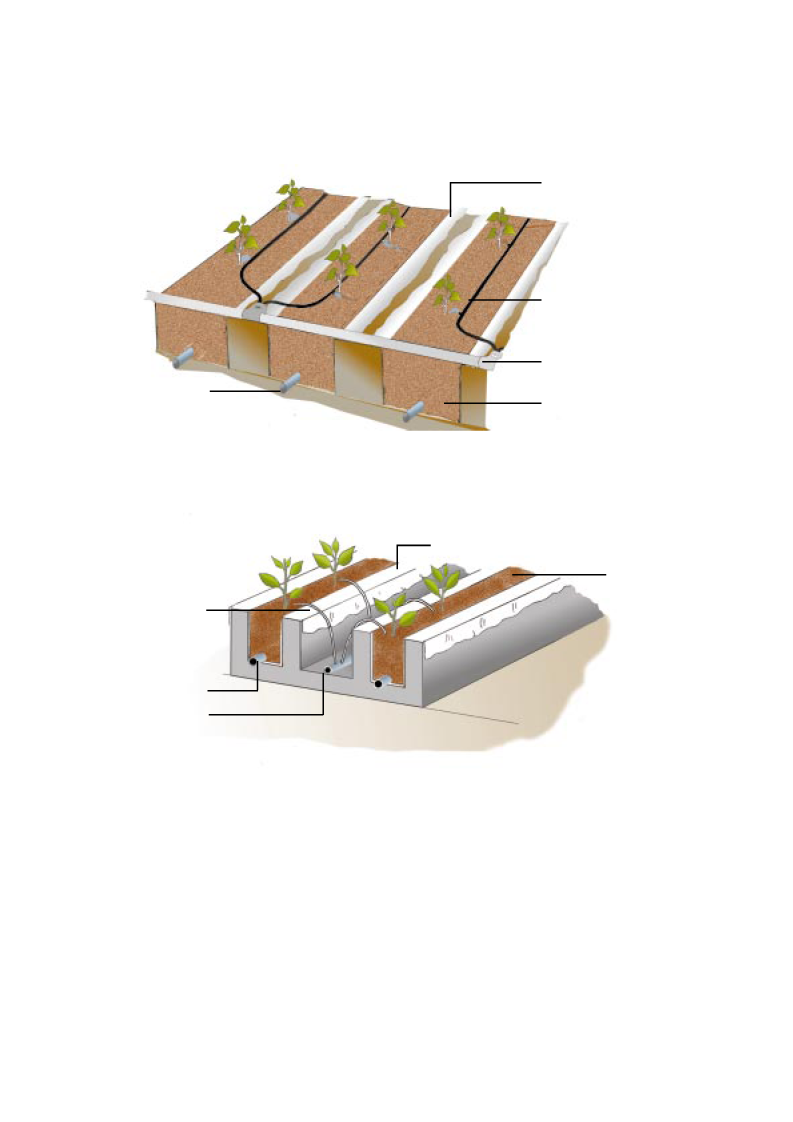

Trench or Trough Technique

In this open system, plants are grown

in narrow trenches in the ground (Figure 27) or

above ground troughs (figure 28) constructed

with bricks or concrete blocks.

Both trenches and troughs are lined

with waterproof material (thick UV resistant

polythene sheets in two layers) to separate

the growing media from rest of the ground.

The width of the trench or trough can be

decided depending on the ease of operation.

Wider trenches or troughs will permit two rows

of plants. The depth varies depending on the

plants to grow and a minimum of 30 cm may

be necessary.

16

Grow bags filed

with coir-dust

Nutrient solution

delivery tube

Nutrien solution

supply line

Figure 25: Diagrammatic view of plants in grow bags

Polythene film

Nutrient solution delivery

pipe

Nutrient solution supply

line

Drainage pipe

Trench filed with growing

medium

Figure 27: Cross section of hydroponic trenches

Polythene film

Trough filed with

growing medium

Nutrient solution

delivery pipe

Drainage pipe

Nutrient solution

supply line

Figure 28: Cross section of above ground troughs

2.5 cm diameter may be placed at the bottom

of the trough or trench to drain out excess

nutrient solution.

Tall growing vine plants (cucumber,

tomato, etc.) need additional support to

withstand the weight of the fruits.

17

Old coir dust, sand or gravel, peat,

vermiculite, perlite, old sawdust or mixture of

these materials can be used as the media for

this culture. The nutrient solution and water

are supplied through a drip irrigation system

or manual application is also possible subject

to labour availability. A well-perforated pipe of

Nutrient solution

delivery pipe

Pot filed with

growing medium

Nutrient solution

supply line

Figure 29: Hydroponics plants in pot technique

The aeroponic culture is usually

practiced in protected structures and is suitable

for low leafy vegetables like lettuce, spinach,

etc.

The principal advantage of this

technique is the maximum utilization of space.

In this technique twice as many plants may be

accommodated per unit floor area as in other

systems. Another potential application of this

technique is in the production of plants free of

soil particles from cuttings for exports.

Nutrient solution mist

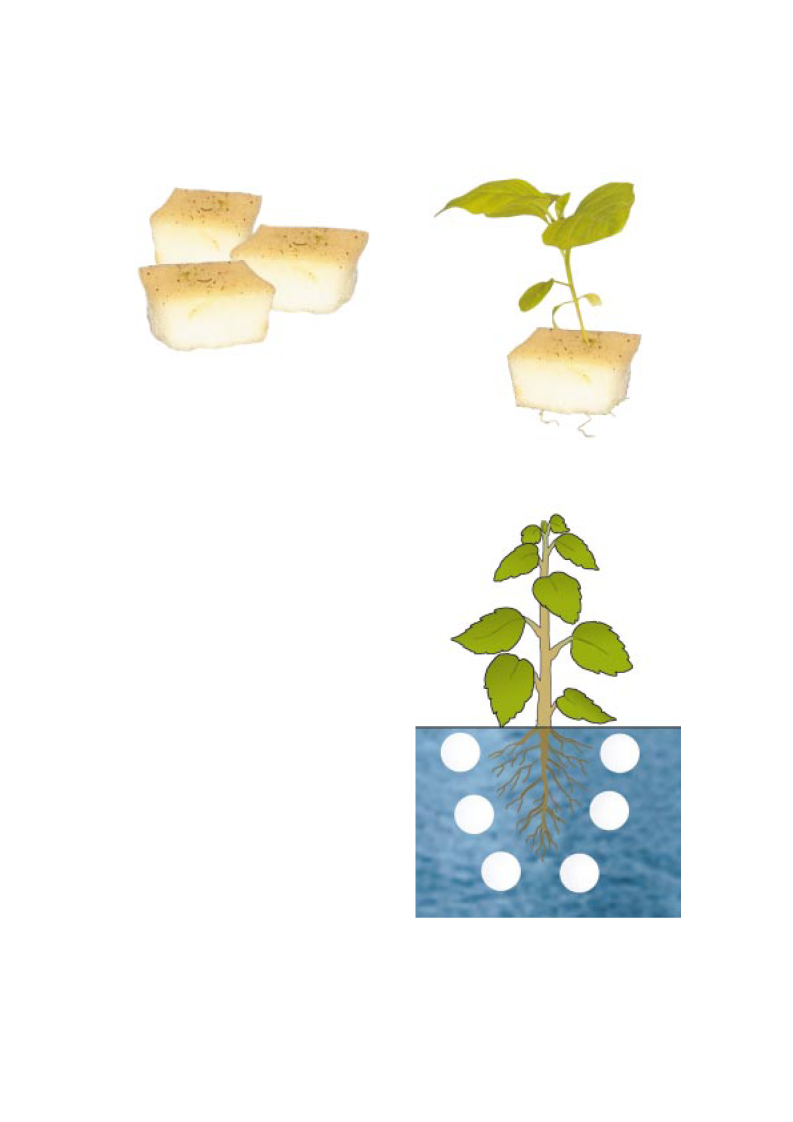

Pot Technique

Pot technique is similar to trench or

trough culture but growing media is filled in

clay or plastic pots (Figure 29). Volume of the

container and growing media depend on the

crop growth requirements. The volume ranges

generally from 01 to 10 litres.

Growing media, nutrient solution

supply, providing support to plants, etc. is

similar to that of trough or trench culture.

Aeroponic Technique

Aeroponic is a method of growing

plants where they are anchored in holes in

Styrofoam panels and their roots are

suspended in air beneath the panel. The

panels compose a sealed box to prevent light

penetration to encourage root growth and

prevent algae growth. The nutrient solution is

sprayed in fine mist form to the roots. Misting

is done for a few seconds every 2 – 3 minutes.

This is sufficient to keep roots moist and nutrient

solution aerated. The plants obtain nutrients

and water from the solution film that adheres

to the roots.

Styrofoam pannel

Plastic lining

Figure 30: Aeroponic A-frame unit, developed by Jensen and Collins in 1985 at the University of Arizona

18

Nursery Containers/ Trays

Use a container that provides the

suitable condition for seed germination and also

according to crop and cultivation method.

Individual containers / Growing blocks:

paper pots, plastic pots, clay pots,

Styrofoam pots, coconut fibre pots, rockwool

blocks, sponge blocks

Figure 31: Some individual containers

Trays:

Styrofoam trays, speedling/cell plug trays

Figure 32: Trays

Trays made up of different materials

are available for sale in market. Depending on

the requirements, trays may be selected.

19

Nursery Techniques for

Hydroponics

As in open field

agr i cul t ur e,

production of

v i g o r o u s

seedlings or

p l a n t i n g

material of

high yielding

varieties is an essential

step of hydroponics/soil-

less culture, to obtain

economic yields.

Nursery Medium

The growing medium must provide

satisfactory conditions for seed germination

and to raise pest and disease free seedlings.

A material that is friable, moderately fertile, well

drained yet have sufficient water holding

capacity and good aeration and free of pests

and disease causing organisms must be

selected as medium for seed germination or

rooting the planting materials.

The following materials can be used

as medium to raise seedlings or to root planting

materials.

- Old coir-dust

- Carbonised rice husk

- Fine sand or fine sand and old coir

dust mixture

- Rockwool, Peat, perlite or vermiculite,

etc.

Sterilize the medium before use. For

coir-dust, add hydrated lime to bring its pH to

neutral. For a 05 kg coir-dust block, about 100

– 250 g hydrated lime is needed.

Gotukola-

Plantlets or runners separated

from mother plants.

Strawberry- Plantlets or runners separated

from mother plants

Gerbera-

Plantlets separated from

mother plants

Mukunuwenna-

10 – 12 cm long semi-

hardwood or hardwood

stem cuttings.

Kang Kong- 20 cm long semi-hardwood

cuttings with 3-4 nodes.

Mint-

10 – 12 cm long semi-

hardwood stem cuttings

Sarana-

Semi-hardwood stem cuttings.

Figure 34: Rooted Kang Kong stem cutting ready

for planting

Nutrient Supply

Nutrient supply is not necessary until the

emergence of first two true leaves. Until such

time apply only clean water. However, when

they unfold, nutrient supply must begin

gradually as the growing medium contains very

little plant nutrients. The fertilizer mixture meant

hydroponics plants could also be used for

nursery plants. Diluted nutrient solution can

be applied every day or nutrient solution

prepared by dissolving 10 g of Albert’s mixture

in 10 litre of water can applied every other day.

20

Seed Germination

Thorough cleaning of the pots followed

by washing with 10% Calcium or Sodium

hypochloride will ensure disease free condition.

Place one seed per block filled with growing

medium at the correct depth in the pots or trays.

Such necessary conditions for seed

germination as moisture, temperature, humidity

must be provided. Germination trays can be

covered with wet papers or cloth to provide

adequate temperature for germination until the

seeds sprout. Remove these papers at the

time of seedling emergence.

Maintain the moisture level of the

medium at correct level for uniform germination

and application of water in the mornings is

preferred.

Planting Material Production

Vegetative parts separated from

mother plants can also be rooted and used as

planting materials. Individual containers or

trays filled with growing medium are used for

rooting these vegetative parts. Select

vegetative parts that are free from pests,

disease causing organisms and nematodes for

propagation. For example, following materials

can be used for propagation.

Figure 33: Selected Kang Kong stem cutting

Once the seedlings or planting

materials reach the correct size for planting,

they can be planted with the medium.

Vegetative parts can sometimes be directly

established in the hydroponics system.

Nursery Period

The nursery period varies with the crops.

Tomato

3 - 4 weeks (2-3 true leaves stage)

Cabbage

4 - 5 weeks (3-4 true leaves stage)

Salad cucumber 3 weeks (3-4 true leaves stage)

Lettuce

2 - 3 weeks

Bell Pepper

4 - 5 weeks

Select vigorous seedlings with the

characteristics for the variety concerned for

establishment in hydroponics. Also tissue-

cultured plants can be established in

hydroponics.

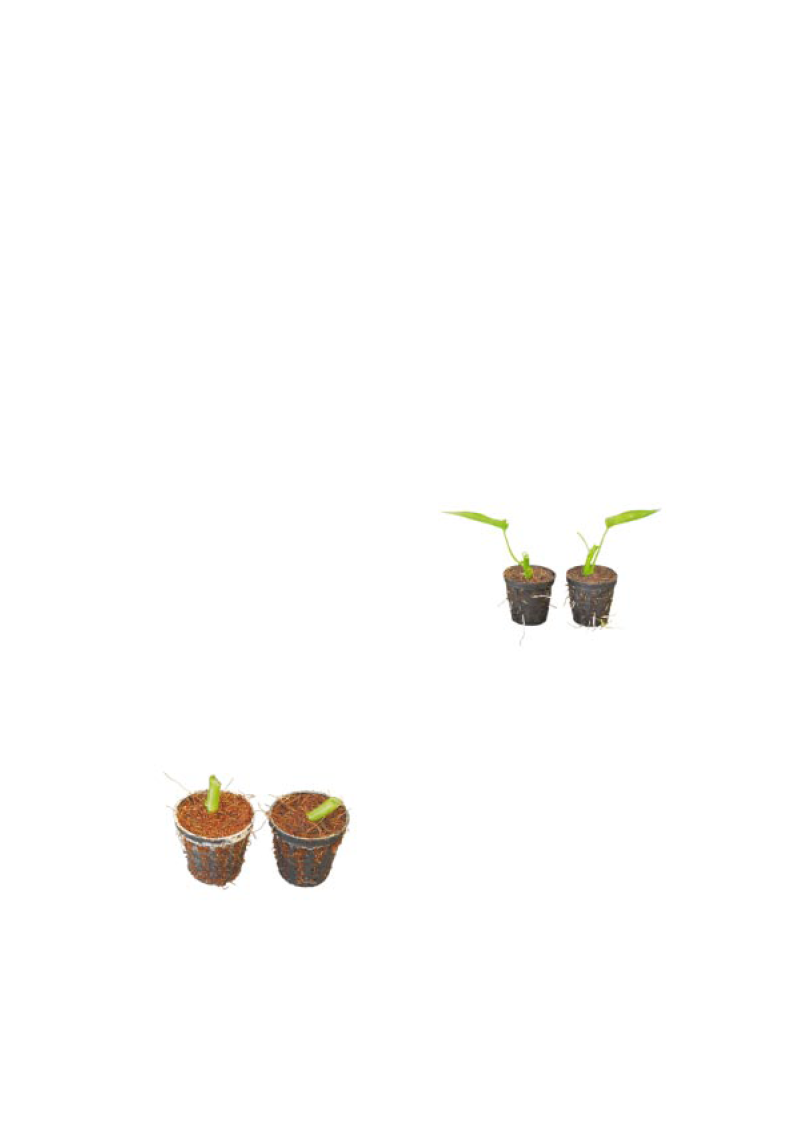

Sponge Nursery Technique

Sponge pieces can be used as nursery

medium instead of the above mentioned media

materials. 2.5 cm cube sponge blocks can be

used for this purpose. Place the seeds at the

centre in a cut made on the topside of the

sponge block.

Sponge nursery is maintained as other

nurseries. Nutrient supply must begin when

the first true leaf begin to unfold. Depending

on the cultivation method, the seedlings can

be planted in hydroponics system with the

sponge block intact. The sponge block may

be removed with minimum damage to roots

when plants begin to grow .

21

At the early stage, place the trays or pots

in shallow containers that is filled with nutrient

solution in such a way that the tray’s or pots’

lower portion is submerged in the solution. The

nutrient solution will reach the media through

the holes at the bottom of the pots or nursery

trays by capillary action. Vegetative parts for

propagation planted in individual containers or

trays are also placed in shallow nutrient solution

containers as seedling trays.

Figure 35: Nursery pots placed in shallow nutrient

solution containers

The nutrient solution can also be applied

directly to nursery pots after seed germination

or sprouting of planting materials. When

applying nutrient solution directly to nursery

pots,

• place the pots or trays on a flat plane

and pour solution so that it does not come

into direct contact with the small plant;

• at the early stage apply 5-10 ml solution

once a day; and

• when plants grow, 10-25 ml a day once or

twice till establishment.

Figure 37: Seedling in a sponge block ready for

transplanting

N

P

K

Fe

S

Mg

Zn

Ni

Mo

Cu

Cl

B

Mn

Figure 36: Sponge block for seed germination

Nutrient Solution for

Hydroponics

Plants require 17 essential elements

for their growth and development. Without

these nutrients plants cannot complete their

life cycles and their roles in plant growth cannot

be replaced by any other elements. These 17

essential elements are divided into macro-

elements (required in relatively large quantities)

and micro or trace elements (required in

considerably small quantities).

The macro elements are carbon (C),

hydrogen (H), Oxygen (O), nitrogen (N),

phosphorous (P), potassium (K), calcium (Ca),

magnesium (Mg) and sulphur (S). The micro

elements are iron (Fe), chlorine (Cl), boron (B),

manganese (Mn), copper (Cu), zinc (Zn),

molybdenum (Mo) and nickel (Ni).

All essential nutrients are supplied to

hydroponics plants in the form of nutrient

solution, which consists of fertilizers salts

dissolved in water. The hydroponic grower must

have a good knowledge of the plant nutrients,

Ca

Figure 38: Plant nutrients in nutrient solution

22

solubility of phosphoric acid, calcium and

manganese drops sharply. The optimum pH

range for hydroponic nutrient solution is

between 5.8 and 6.5.

Figure 39: Measuring nutrient solution pH using a

portable digital pH meter

The further the pH of a nutrient solution

from recommended pH range, the greater the

odds against the success.

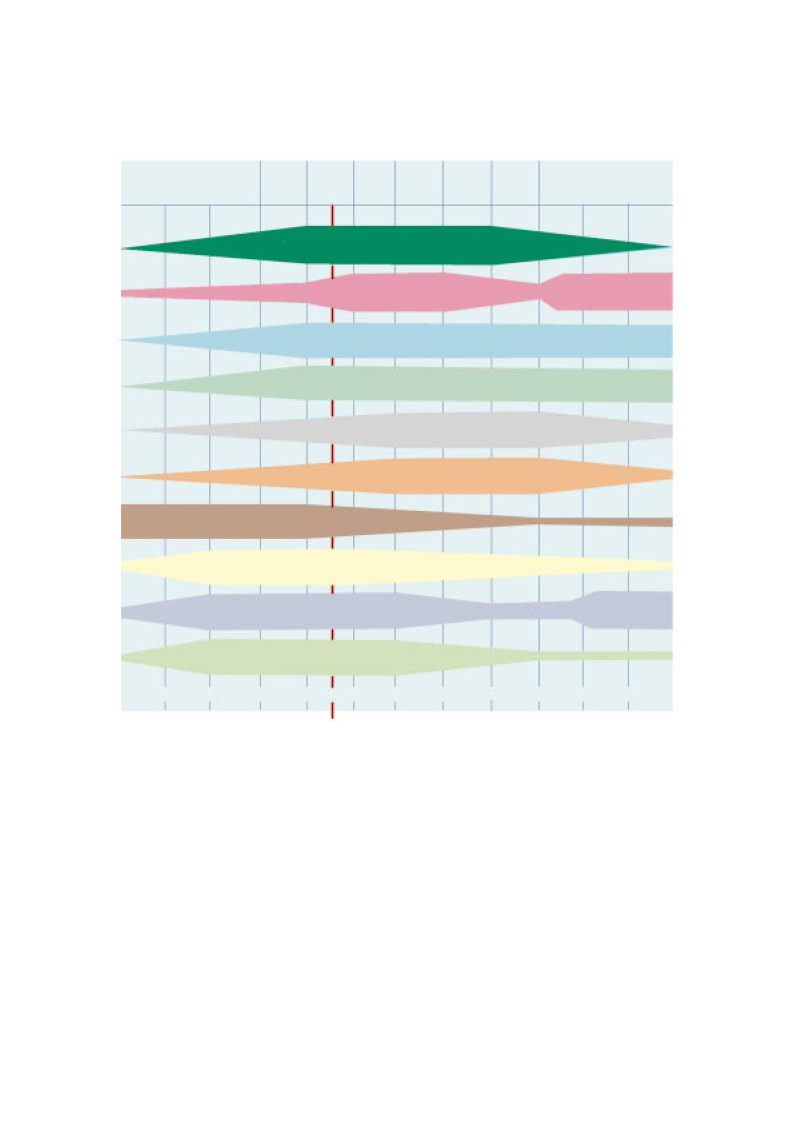

The figure 40 indicates the nutrient

element availability at different pH levels of the

solution. Nutrient deficiencies will become

apparent or toxicity symptoms will develop if

the pH is higher or lower than the

recommended range for individual crops. For

example, if pH is consistently 7.5, one can

expect intra-veinal chlorosis to occur, an

indication of iron deficiency.

23

as management of plant nutrition through

management of nutrient solution is the key to

success in hydroponic gardening.

The hydroponic methods enable

growers to control the availability of essential

elements by adjusting or changing the nutrient

solution to suit the plant growth stage and to

provide them in balanced amounts. As the

nutrients are present in ionic forms in the

nutrient solution and also, not needing to search

or compete for available nutrients as they do

in soil, hydroponic plants reach maturity much

sooner. Optimization of plant nutrition is easily

achieved in hydroponics than in soil.

Nutrient Solution

Management

While optimum nutrition is easy to

achieve in hydroponics, incorrect management

of the nutrient solution can damage the plants

and lead to complete failure. The success or

failure of a hydroponic garden therefore,

depends primarily on the strict nutrient

management programme.

Carefully

manipulating the nutrient solution pH level,

temperature and electrical conductivity and

replacing the solution whenever necessary, will

lead to a successful hydroponic garden.

pH Level

In simple terms, pH is a measure of

acidity or alkalinity on a scale of 1 to 14. In a

nutrient solution, pH determines the availability

of essential plant elements. A solution is

considered to be neutral at pH 7.0, alkaline if

above and acidic if below.

For pH values above 7.5, iron,

manganese, copper, zinc and boron becomes

less available to plants. Should the pH of a

nutrient solution fall below 6.0, then the

strongly alkaline

9.0

9.5

10

strongly acid

4.0

6.0

4.5

5.5

7.5

8.0

5.0

6.5

7.0

6.25

Figure 40: Chart showing the availability of nutrient elements at different pH levels.

The chart shows a pH range of 4.0 to

When plants absorb nutrients and water

10.0. The width of the coloured section for each

from solution, pH of the solution changes.

nutrient represents the availability of that

Therefore, it must be monitored daily, and

nutrient. The widest place denotes the

adjusted to be between the recommended

maximum availability. The narrowest place

ranges. Chemical buffers can adjust the pH of

denotes the least availability. The red line at

a nutrient solution, when it strays outside the

pH 6.25 indicates the maximum number of

ideal. It can be lowered by adding dilute

elements at their highest availability.

concentrations of phosphoric or nitric acids and

24

8.5

very

very

slightly

slightly

acid

acid

alkaline alkaline

Nitrogen

Phosphorus

Potassium

Sulpher

Calcium

Magnesium

Iron

Manganese

Boron

Copper & zinc

slightly slightly

acid alkaline

raised by adding a dilute concentration of

potassium hydroxide. Although it is important

to stay within recommended range, it is far

more important to prevent large fluctuations.

Electrical Conductivity (Ec)

The electrical conductivity indicates the

strength of nutrient solution, as measured by

an Ec meter. The unit for measuring Ec is dS/

m. A limitation of Ec is that it indicates only the

total concentration of the solution and not the

individual nutrient components.

The ideal Ec range for hydroponics

is between 1.5 and 2.5 dS/m. Higher Ec will

prevent nutrient absorption due to osmotic

pressure and lower Ec severely affect plant

health and yield.

Figure 41: Measuring nutrient solution Ec using a

portable digital Ec meter

When plants take up nutrients and water

from the solution, the total salt concentration,

i.e., the Ec of the solution changes. If the Ec

is higher than the recommended range, fresh

water must be added to reduce it. If it is lower,

add nutrients to raise it.

Preparation of Nutrient

Solution

Though hydroponic growers can

formulate their own fertilizer mixtures to prepare

nutrient solutions using completely water-

soluble nutrients salts, a number of

formulations are available in the market to

choose.

It is important to avoid any formulations

that contain impurities like sand, clay or silt.

Such impurities do not supply any nutrients

but they are harmful as they can block the

delivery tubes.

Also avoid any formulation that has

insoluble or less soluble salts. In hydroponics,

the nutrients must be available in solution in

ionic form for plant absorption. If they are found

as salts, plants will suffer from nutrient

deficiency symptoms.

Although urea is completely soluble in

water, it cannot be used in hydroponics, as it

does not break into ionic form in the solution

as it does in soils.

Some fertilizer salts react with each

other to produce insoluble precipitations. For

example, ammonium sulphate and potassium

chloride form less soluble potassium sulphate

in the tank.

Phosphate fertilizers act

problematic in the presence of high calcium

and magnesium concentrations, causing

precipitation of low soluble phosphates.

Therefore, select fertilizers that are compatible

with each other. The table 1 indicates

compatibility of some saltsFertilizer Mixtures

for Hydroponics

25

AN

-

C

C

C

C

C

AS

CAN MAP SOP MOP

C

C

C

C

C

-

L

C

C

C

L

-

X

C

C

C

X

-

C

C

C

L

C

-

C

C

X

C

C

-

Soluble fertilizers

Ammonium nitrare (AN)

Ammonium sulphate (AS)

Calcium nitrate (CAN)

Mono ammonium phosphate (MAP)

Potassium sulphate (SOP)

Potassium chloride (MOP)

Gypsum (G)

Kieserite (KS)

Potassium nitrate (PN)

Table 1: Compatibility chart for some soluble fertilizers

X

X

X

X

C

C

C

C

C

X

C

C

C

L

C

C

-

C

C: compatible, can be mixed in the solution

L: Limited compatibility, mix at the time of use or some precautions must be taken

X: Incompatible, do not mix

Table 2: Chemicals needed to prepare 1000 litres

of nutrient solution proposed by Dr. Alan Cooper.

Fertilizer Mixtures for

Hydroponics

The tables 2 and 3 give nutrient salt

contents of two hydroponics formulations.

These fertilizer mixtures are not suitable

as foliar spray as the EDTA iron (iron chelate)

does not disintegrate easily on plant surface

and therefore, can be harmful to consumers.

Nutrient chemicals

Weight in grams

Potassium dihydrogen phosphate 263.00

Potassium nitrate

583.00

Calcium nitrate

1003.00

Magnesium sulphate

513.00

EDTA iron

79.00

Manganese sulphate

6.10

Boric acid

1.70

Copper sulphate

0.39

Ammonium molybdate

0.37

Zinc sulphate

0.44

26

Table 3: Chemicals needed to prepare 1000

litres of nutrient solution (Albert’s mixture,

locally available in the market).

Nutrient chemicals

Weight in grams

Multi-K (Potassium nitrate)

38.00

Refined grade calcium nitrate

952.00

Magnesium sulphate

308.00

EDTA iron

8.00

Zinc sulphate

0.15

Boric acid

0.20

Manganese sulphate

1.15

Copper sulphate

0.10

Mono potassium phosphate

269.00

Potassium sulphate

423.00

Ammonium molybdate

0.03

Figure 42: Fertilizer mixing tank

Fertigation

Fertigation combines the two main

factors of supplying water and plant nutrients

that are essential for plant growth. The right

combination of the two is the key to obtain

high yields and quality produce.

Advantages of Fertigation

• Accurate and uniform application of

fertilizers

• Ability to meet plant nutrient demand under

given climatic conditions and during different

crop growth stages

• Improving fertilizer use efficiency and

reducing leaching below root zone thus

minimizing pollution

• Saving on labour

• Increasing both yield and quality of produce

Factors to be Considered in

Fertigation

1.

Growing media

2.

Fertilizers used

3.

Irrigation water quality

As the first two factors were discussed

earlier, only irrigation water quality is discussed

here.

27

crops, crop growth stage and the hydroponics

technique used. The example below explains

this situation.

However, at all stages of crop growth, the pH

of the nutrient solution must be maintained

between 5.8 - 6.5 and Ec between 1.5 - 2.5

dS/m.

For circulating techniques (DFT and

NFT), supply the nutrient solution for a

predetermined time period.

For aggregate systems (solid media

culture), fertigation can be done manually or

through drip irrigation system. Supply the

fertilizers with irrigation water for a

predetermined time period so that the water

content of the growing media does not increase

beyond field capacity. When fertigation is not

done, the crop must be irrigated with water to

maintain the medium at field capacity.

Quality Factors

pH

Salinity Ecw

Sodium

Chloride

Boron

Bicarbonates

Unit

Water Quality classes

Non-hazardous

Slight to Moderate

Severe

--- Normal Range 6.5 - 8.4 ---

dS/m

me/lit

me/lit

mg/lit

0.00 – 0.8

0.8 – 3.0

3

3

3

-

3

3

-

0.7

0.7-3

3

Irrigation Water Quality

Use good quality water with its pH and

Ec suitable for plant growth. Based on pH, Ec

and soluble salt content, water quality can be

divided into 03 classes (Table 4).

Non-hazardous and medium class water

can be used for fertigation. However, when

latter is used for fertigation, thoroughly leach

the growing medium at least once a year.

Methods of Fertigation

Mix the fertilizers required for a particular

crop with daily water requirement of that crop

and apply manually or through fertigation

system.

The amounts of fertilizers mixed with

irrigation water will vary depending on the

Table 4: Irrigation water quality classes

me/lit

1.5

1.5-8.5

8.5

(Courtesy: Guidelines for interpretation of water quality for irrigation. Western fertilizer handbook.

Page 38).

28

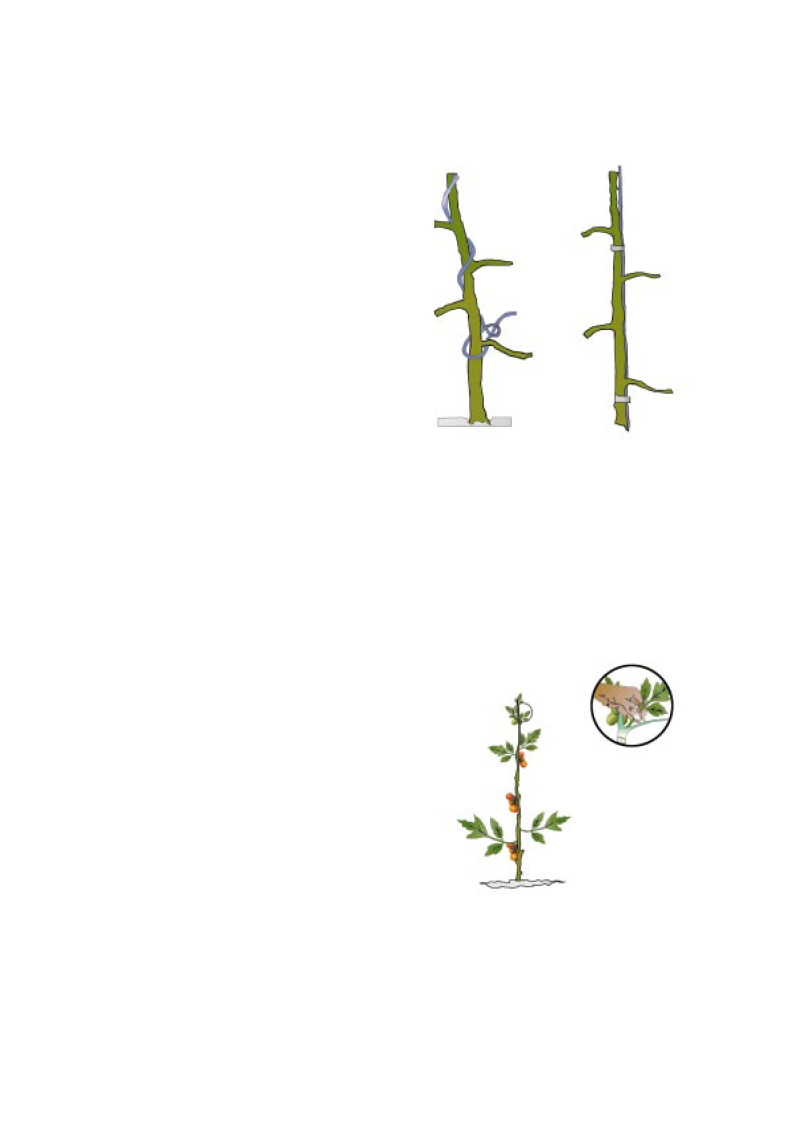

Figure 43: Training plants on vertical support.

the string from the overhead horizontal support

and lower the plants about 60 cm and tie the

string shifting to a side (figure 45). This must

be done every 2 weeks, and the strings must

be long enough to permit lowering during the

entire cropping period.

Figure 44: Removal of side branches in tomato

plants

29

Training and Pruning

In hydroponics, the growing medium

does not provide enough anchorage as soils.

This is more so in liquid cultures as no planting

medium is used. Therefore, growers must

provide artificial supporting structures and train

plants along those structures. Support is

especially important, when tall growing

indeterminate type crop varieties (tomatoes,

cucumber, etc.) or crops bearing relatively

heavy fruits (bell pepper, egg plant, etc.) are

used in hydroponics.

A polythene string can be tied at the

base of each plant using a plastic plant clip or

by a loose non-slip knot as shown in figure 43

and the string is tied vertically to the overhead

horizontal support to hold the plants. When

plants grow, wind the main stems loosely

around the string for support. In the case of

tall growing indeterminate tomato varieties,

placing additional plant clips every 3rd to 4th

nodes will be necessary to prevent the plants

from slipping down.

For salad cucumbers, the vertical

string is attached to each plant with plastic plant

clips or by a loose non-slip knot at the base.

As the plants grow, wind the main stem loosely

around the string for support. Additional plant

clips are attached to prevent plants from

slipping.

Tall growing indeterminate type

tomatoes are trained to a single stem. All lateral

branches are removed when they are about 5

cm long (Figure 44). Prune the lateral branches

every 3 – 4 days, and it is best done early in

the day.

Indeterminate type tomato plants that

produce long term crops are lowered to a

working height as they grow, keeping

production limited to fruit grown on the 2 – 2.5

m of the main stem. When plants grow taller,

remove about 04 leaves at the bottom and untie

Figure 46: The umbrella training system for

cucumber

Bell pepper plants are trained to two

stems. Vertical strings tied to overhead

horizontal support, support them. Guide these

side stems to the vertical strings. Flowers occur

in axils of each branch. Side shoots arising

from the stems must be pruned after 2 – 3

leaves so that fruiting takes place only on the

two main branches. Periodic fruit thinning may

be required to obtain large, good quality fruits.

30

Tomatoes produce large number of fruits

at each cluster. To get large, quality fruits, fruit

thing will be necessary. Depending on the size

required, 3 to 5 fruits may be left in a cluster.

For salad cucumbers, umbrella system

of pruning can be adopted. It involves pruning

all lateral branches until the plant reaches the

overhead horizontal support (figure 46). There,

the terminal bud is removed and two side

branches are allowed to grow downwards.

Vigorous plants will continue to produce fruits

Figure 45: Tomato plant at left will be lowered the

position at right by retying the support string to the

overhead horizontal support several cm to the

right

on the downward growing lateral branches,

although the rate of fruit production tends to

slow down.

Salad cucumber may produce more than one

fruit per node; these can be thinned out to one

fruit per node or allowed to develop if they are

not curved or otherwise distorted in shape.

Heavy fruiting at lower part of the vine will

reduce production higher up.

• Maintain adequate solution temperature. As

the temperature goes up, plant respiration

increases causing a higher demand for

oxygen. At the same time, the solubility of

oxygen decreases. This requirement is

more critical in green houses and net

houses where the temperature is bound to

increase during mid afternoons. Steps must

be taken to counter such increase.

• Always ensure that there is plenty of

dissolved oxygen in the nutrient solution as

the plant roots absorb oxygen. Lack of

oxygen will reduces up take of nutrients and

thereby the yield and also causes root rot.

In closed systems, if the recollected solution

is allowed to fall into the solution tank from

a height, natural aeration will take place.

• In root dipping techniques, maintain

adequate air space above the nutrient

solution in the container as success

depends on the rapid growth and quantity

of roots that are exposed to the air. These

roots absorb oxygen for the plants. Ideally,

top two thirds of the young root system must

be in the air and the rest must be floating

in the nutrient solution.

Figure 48: Luxuriant growth of water and air

absorbing roots takes place when there is

adequate air space above solution

31

Management

Requirements of

Hydroponics/

Soil-less Culture

Meet the following requirements to

develop and maintain a successful

hydroponics/soil-less cultivation of crops. If

any of these conditions are not fulfilled, one

cannot obtain economical yields.

• Maintain the nutrient solution pH in the

range of 5.8 to 6.5, and electrical

conductivity (Ec) in the range of 1.5 to 2.5

dS/m, as these ranges are suitable for plant

growth. Any pH or Ec outside these ranges

will reduce availability and uptake of

nutrients and will also damage plant roots.

Plants are the best indicators of the nutrient

availability. Look for nutritional disorder

symptoms in plants and adjust nutrient

solution accordingly (Figure 47).

Figure 47: Iron deficiency symptom in strawberry

• Avoid any sudden changes in nutrient

solution concentration as it can result in

unsuitable pH and Ec.

• In root dipping techniques, during crop

growth, when the solution level in the

container goes down, the ion concentration

may increase. Such increase is detrimental

to plant growth. If this condition is observed,

siphon out the remaining solution and refill

with fresh solution.

• Ensure adequate light for the hydroponics/

soil-less culture plants. Light and all other

requirements are the same as though grown

in open fields.

• Always use pest and disease free seedlings

and planting materials for establishment of

hydroponics crops. Remove and destroy

any infected plants as soon as they are

found.

• If nematode problem is observed in solid

media culture, discard the plants and

sterilize the growing medium. If in doubt,

discard and replace the medium. Also

ensure that he water supply is also free

from nematodes.

• Algae can build up in the system and block

the small tubes used for the delivery of

nutrient solution. Use black colour tubes to

avoid such problems. Between crops,

thoroughly clean the system using a mild

solution of chlorine. After cleaning,

thoroughly flush the system with fresh water

before replanting.

• Adequate spacing is necessary for plant

growth and when vine crops are grown,

supports must be provided.

• In open aggregate techniques, there is a

possibility for nutrients to leach when water

is applied. Therefore nutrient solution may

be applied continuously instead of water to

supply both water and nutrients.

Soil-less Culture and

Controlled Environment

Agriculture

Hydroponics culture is probably the

most intensive method of crop production in

today’s agricultural industry. In combination with

green houses and protective covers (controlled

environment agriculture), it is high technology

and capital intensive. With the possibility of

adjusting air and root temperature, light, water,

plant nutrition, and adverse climate, this

combination can be made highly productive,

conservative of water and land and protective

of the environment.

Figure 49: Protected structure

Advantages

High-density maximum crop yield, crop

production where no suitable land exists, crop

cultivation regardless of seasonality, more

efficient use of water and fertilizers and minimal

use of land area are the principal advantages

of soil-less culture in combination with

controlled environment agriculture. Another

32

by the use of mechanical vibrators. Blowers

can be used to improve the airflow inside the

structures.

Hormones may also be used to

increase the chances of pollination inside

protected structures. For example, 0.15% 4-

CPA (Para chlorophenoxy acetic acid - a kind

of auxin) is widely used to induce fruiting of

tomato in Japan. Hormone application is

effective for tomato 3 days before and 3 days

after blooming. Application more than once,

higher concentration or too early application

can result in malformed fruits.

Some Problems and

Solutions in

Hydroponics

As experienced in normal crop

husbandry, pests diseases and too affect

hydroponics plants and they also show

physiological as well as nutritional disorders

under unfavourable conditions.

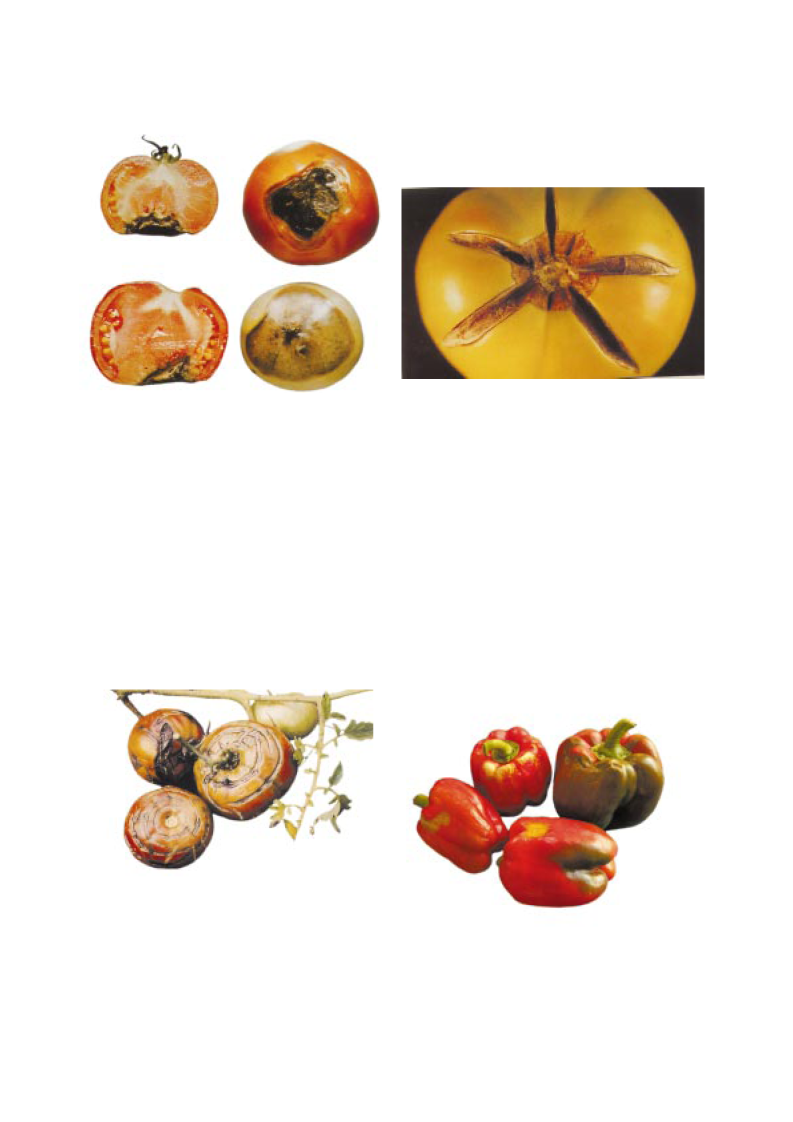

Physiological Disorders

Sudden changes in environmental

factors, incorrect nutrition supply or irrigation

can bring about physiological disorder

symptoms in plants. Some crop varieties are

more prone to these conditions than others.

Blossom end rot of tomato

At the bottom end of tomato fruits, brown,

sunken leathery spots appear (Figure 50).

Calcium deficiency, dry growing medium and

sudden supply of water, salt accumulation in

root zone are some causal factors. Avoiding

these conditions will prevent blossom end rot.

33

major benefit is the possibility of obtaining

pesticide free products, which fetch higher

prices at the increasingly ready markets, at

present.

Precautions

High temperature

One serious concern in Sri Lanka and

other tropical countries is the rise of solution

temperature during mid afternoons in green/

net houses and under protective covers.

Adoption of closed system of hydroponics

where the solution is recycled helps reduce

such rise in temperature to some extend.

Further, misting of water to crops when

temperature rises, use of exhaust fans, use of

white colour containers to hold solutions,

painting gullies/pipes with white colour, etc. will

help reduce the build up of heat from sunlight.

Sunlight

In protected structures, it was

observed that growth and yield of plants of

inner rows of hanging bag and grow bag

techniques were poor due to low sunlight

availability. Therefore, ensure that enough

sunlight reaches the inner rows of these

techniques.

Pollination

As protected structures effectively

prevent insects reaching crops, pollination by

insects does not take place in the protected

structures. Also lack of natural airflow also

reduces the chances of natural pollination.

High temperatures normally experienced inside

protected structures also interfere with

pollination as it reduces pollen viability.

Therefore, artificial pollination must be done

Figure 50: Blossom end rot of tomato

Concentric fruit cracking of tomato

Concentric cracks appear around the

fruit stalk (Figure 51) or cracks extending from

fruit stalk (Figure 52) appear. High day

temperatures, large differences between day

and night temperature and sudden change in

growing media moisture content are the causes

of this condition.

Figure 51: Concentric fruit cracking of tomato

Figure 52: Cracks extending from stalk

Shrink cracks of bell pepper

Shrink cracks appear commonly around

the fruit shoulders. Rapid evaporation of

condensed moisture on fruit surface causes

shrink cracks. Gradual change from day to

night temperatures and night ventilation can

prevent this condition.

Figure 53: Shrink cracks of bell pepper

34

Fruit crooking of cucumber

Fruit crooking is a serious physiological

disorder in cucumber (Figure 54). The

curvature of known as fruit crooking begins at

early stages of fruit development and may be

caused by adverse temperature, excessive

moisture in growing medium, poor nutrition,

excessive fruit load or insect damage. Affected

fruits must be removed as soon as noticed.

Figure 54: Fruit crooking of cucumber

Insect Pest and

Disease Damage in

Hydroponics

In hydroponics, soil borne diseases are

virtually eliminated. Certain common pests and

diseases however, can affect these plants.

Vigilance and early identification are important

in controlling such problems. Keep the

environment of the hydroponics plants clean

and adopt correct cultural practices such as

supply of well-balanced nutrients to maintain

the plants healthy. Pests and diseases less

affect healthy plants. Always start the

cultivation with healthy seedlings/planting

materials.

Adopt Integrated Pest Management

(IPM) strategies recommended for vegetables.

If necessary apply recommended chemicals

to control insect pests or diseases and always

strictly adhere to recommended pre-harvest

intervals.

Nutritional Disorders

In hydroponics all the essential

nutrients are supplied through the nutrient

solution. If the solution is deficient or excess

(toxic) in any of these nutrients or the pH or

the Ec of the solution is beyond the suitable

range, the plants will show nutritional disorder

symptoms.

These symptoms include changes in

growth rate, size of plants, leaf shape and

colour, leaf thickness, stem colour, inter node

distance, nature of root system, etc. In addition,

fruiting characteristics may change. Although

these external symptoms vary according to

crops and varieties, some common symptoms

are described in table 5 and figures 55 to 62.

35

Nutrient Element

Excessive/Toxicity symptoms

Nitrogen

Phosphorus

Pottassium

Sulfur

Magnesium

Calcium

Deficiency Symptom

Growth is restricted and plants are generally Plants usually dark green in

yellow (chlorotic) from lack of chlorophyll, colour abundant foliage but

especially older leaves. Younger leaves remain usually with a restricted root

green longer. Stems, petioles and lower leaf system.Flowering and seed

surfaces of tomato can turn purple.

production can be retarded.

Table 5: Some common nutritional disorder visual symptoms exhibited by plants

No primary symptems yet

noted. Sometimes copper and

Zinc dificiency occurs in the

presence of excess

Phosphorus.

Usually not exesively absorbed

by plants. Exess potassium

may lead to magnesium

dificiency and possible

manganese, zinc or iron

dificiency.

Reduction in growth and leaf

size. Leaf symptoms often

absent or poorly defineed.

Sometimes intervienal yellowing

or leaf burning.

Very little information available on

visual symptoms.

No consistent visible

symptoms.Usually associated

with excess carbonate.

36

Plants are stunted and often a dark green

colour. Anthocyanin pigments may acumulate.

Dificiency sympems occur first in mature

leaves. Plant maturit is often delayed.

Symptoms first visible on orlder leaves. In

dicots, these leaves are initially chlorotic

but soon scattered dark necrotic lesions

(dead areas) develop. In many monocots,

the tips and margins of the leaves die first.

It not often encountered. Generally yellowing

of leaves, usually first visible in younger leaves.

Intervienal chlorosis which first develops on

the older leaves. The chlorosis may start at

leaf margins or tip and progress inward

intervienally.

Bud development is inhibited and root tips often

die.Young leaves are affected before old leaves

and become distorted and small with irregular

margins and spotted or necrotic areas.

Deficiency Symptom

Excessive/Toxicity symptoms

not often evident in natural

conditions. Has been observed

after the application of sprys

where it appears as necrotic spots.

Burning or firing of leaf tip or

margins. Bronzing, yellowing and

leaf abscission and sometimes

chlorosis. Reduced leaf size and

lower growth rate.

Some times chlorosis, uneven

chlorophyll distribution. Reduction

in growth.

Yellowing of leaf tip followed by

progressive necrosis of the leaf

beginning at tip or margins and

proceeding toward midrib.

Exess zinc commonly produces iron

chlorosis in plants.

Reduced growth followed by

symptoms of iron chlorosis,

stunting, reduced branching,

thickening and abnormal darkening

of rootlets.

Rarely observed. Tomato leaves turn

golden yellow.

37

Nutrient Element

Iron

Chlorine

Manganese

Boron

Zinc

Copper

Molybdenum

Pronounce intervienal chlorosis

similar to that caused by

magnesium deficiency but on the

younger leaves.

Wilted leaves which then become

chlorotic and necrotic,eventually

attaining a bronze colour. Roots

become stunted and thikened near

tips.

Initial symptoms are often intervienal

chlorosis on younger or older leaves

depending on species. Necrotic

lesions and leaf sheding can develop

later.

Symptoms vary with species. Stem and

root apical meristems often die. Root

tips often become swollen and

discoloured. Internal tisues sometimes

disintegrate (or discolour) (e.g.”heart

rot” of beets). leaves show various

symptoms including thikening,

brittleness,curling, wilting, and chlorotic

spotting.

Reduction in internode length and leaf

size. Leaf margins are often distorted

or puckered. Sometimes intervienal

chlorosis.

Natural deficiency is rare. Young leaves

often become dark green and twisted

or misshapen, often with necrotic spots.

Often intervienal chlorosis developing

first on older or midstem leaves, then

progressing to the youngest (similar to

nitrogen deficiency). sometimes

marginal scoching or cupping of leaves.

Table 5: Continued

Figure 57: Manganese deficiency in tomato

Figure 61: Magnesium deficiency in tomato

Figure 58: Iron defRiciency in tomato

Figure 62: Sulphur deficiency in strowberry

Pictures curtsey: Compendium of strawberry diseases and compendium of tomato diseases

by American Pathological Society.

38

Figure 59: Nitrogen deficiency in tomato

Figure 60: Zinc deficiency in strowberry

Figure 55: Calcium deficiency in strowberry

Figure 56: Iron deficiency in strowberry

Limitations of

Hydroponics/

Soil-less Culture

• Higher initial capital expenditure. This will

be further high if the soil-less culture is

combined with controlled environment

agriculture.

• High degree of management skills is

necessary for solution preparation,

maintenance of pH and Ec, nutrient

deficiency judgment and correction,

ensuring aeration, maintenance of

favourable condition inside protected

structures, etc.

• Considering the significantly high cost, the

soil-less culture is limited to high value crops

of the area of cultivation.

• A large-scale cultivator may have to

purchase instruments to measure pH and

Ec of the nutrient solution.

• Energy inputs are necessary to run the

system.

• Yields were found to decrease when

temperature of the solution rises during

warm periods.

39

Advantages of

Hydroponics/

Soil-less Culture

• Land is not necessary. It can be practiced

even in upstairs, open spaces and in

protected structures.

• Clean working environment. The grower will

not have any direct contact with soil.

• Low drudgery. No need of making beds,

weeding, watering, etc.

• Continuous cultivation is possible.

• No soil borne diseases or nematode

damage.

• Off-season production is possible.

• Vegetable cultivation can be done with

leisure sense.

• Many plants were found to give yield early

in hydroponics system.

• Higher yields possible with correct

management practices.

• Easy to hire labour as hydroponics system

is more attractive and easier than cultivation

in soil.

• No need of electricity, pumps, etc. for the

non-circulating systems of solution culture.

• Possibility of growing a wide variety of

vegetable and flower crops including

Anthurium, marigolds, etc.

• Water wastage is reduced to minimum.

• Possible to grow plants and rooted cuttings

free from soil particles for export.

Fodder crops -

Sorghum, Alphalfa, Barley,

Bermuda grass, Carpet

grass

Cereals -

Rice, Maize

Condiments -

Parsley, Mint, Oregano,

Sweet basil

Fruit crops -

Strawberry,

Flower/ornamental crops - Anthurium,

Merrygold, Coleus, roses,

carnations, orchids,

chrysanthemums,

Medicinal crops - Alovera

Harvesting, Grading,

Storage and Marketing

Harvesting

Harvesting at correct maturity will reduce

post harvest loses. One must know the age of

the fruits or plants to correctly identify maturity.

Reports on crops may be maintained for this

purpose. Harvest fruits by cutting with a sharp

knife with minimum damage to fruits and plant

stem.

Crops to Grow with

Hydroponics/

Soil-less Culture

A variety of crops can be grown using

hydroponics/soil-less culture. However, priority

must be given to high-value crops depending

on the market situation.

Leafy vegetables - Lettuce, Head lettuce,

Kang kong, Gotukola

Vegetables -

Tomato, Egg Plant, Green

bean,Beet, Winged bean,

Capsicum,Bell pepper,

Cabbage,Cauliflower,

cucumbers, melons,

raddish

Figure 63: Some crops that can be hydroponically grown

40

Harvest bell pepper after they develop

their standard colour. For salads, harvests

before the fruits reach full red ripen stage; when

they are at yellow-red stage. It is better to

wear a pair of gloves while harvesting and use

disinfected knife or scissors.

At least some colour should be

showing in tomato fruit before harvest. If the

stems are attached care should be taken during

handling to avoid any cuts or bruises.

Cucumbers must be harvested with no

attached stem when they reach a uniform

diameter throughout the fruit length, but before

any yellowing appears at the blossom end.

Harvest strawberry fruits when they begin to

turn red.

Leafy vegetables must be harvested

before they reach their full maturity. Select the

correct stage of maturity for ornamental plants

and fruits depending on the market

requirements.

Grading

When the harvest is in fruit form,

discard odd shaped, damaged, or spotted fruits

and grade according to their sizes into large,

medium and small size groups. It may be

suitably labelled to indicate its quality (for

example, free of pesticides).

Storage

After grading, most vegetables must

be stored in cool dry place. Storing in large

plastic containers with large holes for aeration

is advisable.

Marketing

Depending on the market requirement,

produce can be sold in small packing. They

can be suitably labelled. The packing must

have aeration holes.

Figure 64: Packing of tomato for marketing

41

Equipment for

Hydroponics

Submersible or ordinary water pumps,

Ec meter, pH meter are the essential equipment

necessary to operate a circulating hydroponics.

PVC pipes can be used as channels in these

systems.

Water Pumps

The water pump must be made up of

materials that are non-reactive with nutrient

salt solution.

Stainless steel shaft,

polycarbonate or stainless steel impeller, pump-

house and water seal must be there in the

pump to be used in hydroponics.

One does not require a pump with very

high head for circulating the nutrient solution

in hydroponics systems. Therefore, a domestic

water pump with 0.5 HP will suffice. A safety

device is a must with the water pump as the

nutrient solution more effectively conducts

electricity compared to water. Therefore, a very

sensitive trip switch must be used to disconnect

electricity supply whenever the need arises.

Figure 65: A domestic water pump

Figure 66: A submersible water pump

42

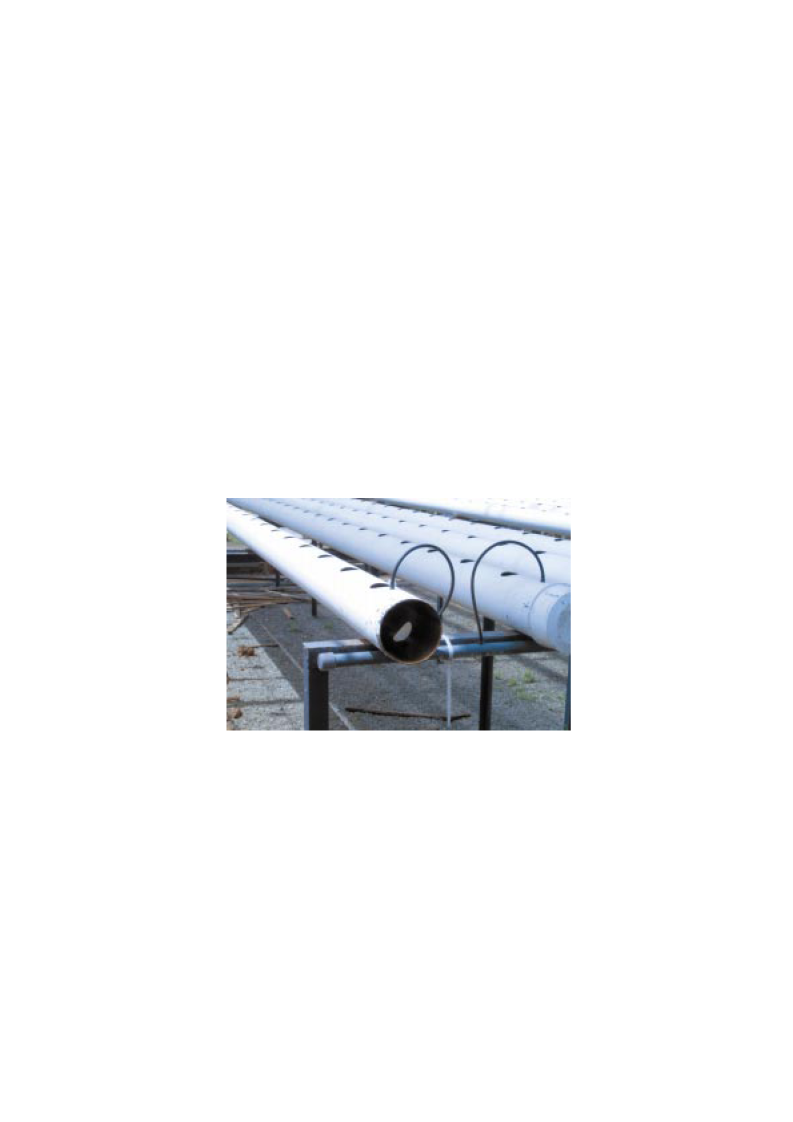

Figure 67: PVC pipe system for hydroponics

43

PVC Pipes

Type 400 or class 4 100 mm PVC pipes

have to be used in circulating hydroponics as

the channels. PVC pipes with thinner walls

will sag and thereby reduce the flow rate of

nutrient solution. The result will be lack of

oxygen supply for the plant roots. UV resistant

pipelines are preferable. Painting these pipes